3D printers have become versatile, affordable, and powerful enough to print all sorts of things — including car parts. The process has also developed beyond DIY and prototyping (there are even 3D printers capable of printing an entire house), and automotive manufacturers have embraced the new technology on an industrial scale. This tech lets you build layers of material directly from digital designs out of such a wide variety of materials that you can make almost anything. That opens the door to making custom or hard-to-find components without traditional tools or inventory. The good news is that you don’t need an expensive industrial printer for a lot of parts, especially the cosmetic ones.

But even if you can print something, that doesn’t mean it’s roadworthy, or even road legal. Vehicle inspections focus on safety-critical systems, and printed parts may compromise roadworthiness. That’s why it’s essential to understand what can and can’t be 3D printed, which materials to use, and how to navigate the legal implications of 3D printing car parts. In general, non-critical parts that don’t carry heavy loads can typically be created with this tech, and it can be one of the best ways to customize or restore your vehicle.

What can and can’t be 3D printed

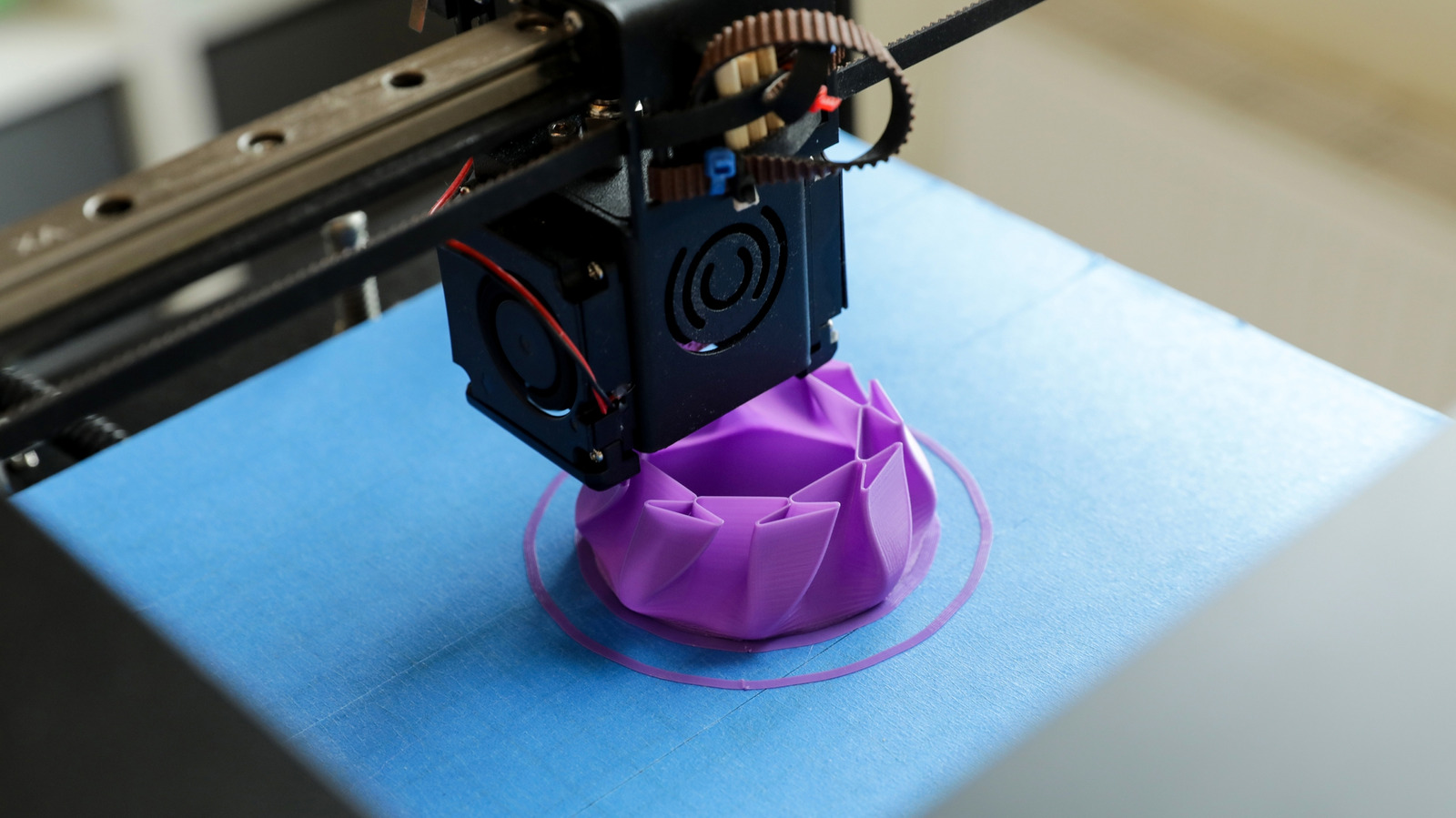

The auto industry is already using 3D printing, also known as additive manufacturing, to produce some car parts. Interior pieces such as dashboard panels, air vents, and switch housings are a perfect example of car parts that can be printed. These parts don’t carry heavy loads, and it’s simply faster and cheaper to 3D print them. The same goes for some exterior pieces such as grilles, mirror housings, or small aerodynamic add-ons. Their complex shapes and curves can easily be achieved with the freedom that comes with printing design.

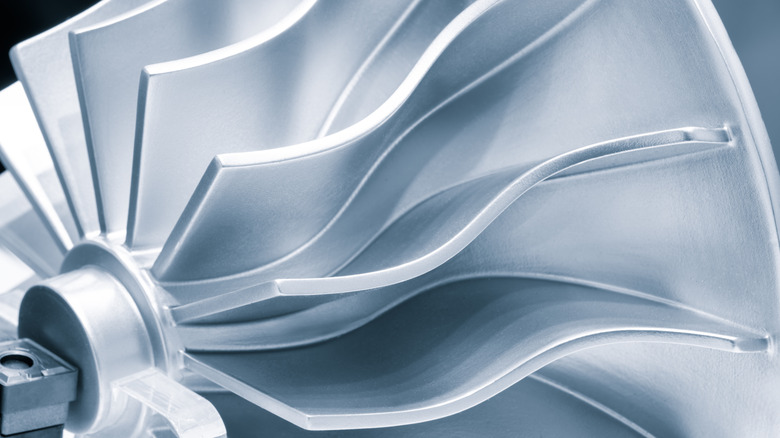

Even some parts under the hood are being 3D printed. Typically, they’re non-critical pieces like engine covers or air intake ducts. Heat-resistant polymers are a perfect material to use for printing these kinds of interior parts. Brackets, clips, and mounting parts can also be printed, especially if you need to replace the original designs. Typically, for high-performance cars, the industry uses metal 3D printing techniques to produce brackets and fasteners out of aluminum or titanium. These strong yet light materials are already in use — the only thing that changes is the production technique.

But it’s important to know that not everything can be 3D printed — the technology is simply not quite there yet. Although a father and son team has tried to 3D print a Lamborghini, printers have a size and speed limit. Given these limitations, load-bearing chassis components are still made the traditional way. Safety-critical parts like the steering system and full suspension arms also cannot be easily 3D printed because current materials don’t meet the strict strength, durability, and heat resistance requirements. 3D printing with advanced materials that meet safety requirements is very limited. Even when it is possible, it’s too slow and expensive.

When does 3D printing car parts make sense

With 3D printing, you can create things that traditional manufacturing isn’t ideal for, like personalized gear shift knobs, cup holders, mirror covers, and unique license plate frames. The tech is also great for customizing certain car parts and replacing hard-to-find or expensive parts. If you love classic vehicle restoration, 3D printing is the way to go. The prices that come with the old-timer restoration have made many car enthusiasts give up their dreams. 3D printing allows you to create exact replicas of those missing parts without demolishing your bank account. That said, if you’re inexperienced with the tech, you might want to first try a few 3D printing projects for beginners to get used to the process.

The best part is that it’s legal to 3D print certain parts for your own car, though you do need to check with local legislation. You also need to make sure you’re not violating any patents or trademarks, and you cannot sell the parts commercially. When it comes to vehicle inspection, you must make sure your 3D-printed components do not compromise road safety. That’s why it’s important to use the right materials for the right designs.

You should never use PLA or brittle resins to print car parts, especially not heat- or load-bearing pieces. They simply won’t last you long. You need materials that can withstand heat, automotive fluids under pressure, constant vibration, UV radiation, mechanical stress, and impact stress. Ideally, opt for PEEK and ULTEM 9085, the premium materials, though carbon fiber and Nylon PA6 are also good options. If you need UV resistance for the exterior part, choose ASA. With the right material, you can design and print a lot of parts for your car and potentially save thousands of dollars in the process.