Authors:

(1) Jorge Francisco Garcia-Samartın, Centro de Automatica y Robotica (UPM-CSIC), Universidad Politecnica de Madrid — Consejo Superior de Investigaciones Cientıficas, Jose Gutierrez Abascal 2, 28006 Madrid, Spain ([email protected]);

(2) Adrian Rieker, Centro de Automatica y Robotica (UPM-CSIC), Universidad Politecnica de Madrid — Consejo Superior de Investigaciones Cientıficas, Jose Gutierrez Abascal 2, 28006 Madrid, Spain;

(3) Antonio Barrientos, Centro de Automatica y Robotica (UPM-CSIC), Universidad Politecnica de Madrid — Consejo Superior de Investigaciones Cientıficas, Jose Gutierrez Abascal 2, 28006 Madrid, Spain.

Table of Links

Abstract and 1 Introduction

2 Related Works

2.1 Pneumatic Actuation

2.2 Pneumatic Arms

2.3 Control of Soft Robots

3 PAUL: Design and Manufacturing

3.1 Robot Design

3.2 Material Selection

3.3 Manufacturing

3.4 Actuation Bank

4 Data Acquisition and Open-Loop Control

4.1 Hardware Setup

4.2 Vision Capture System

4.3 Dataset Generation: Table-Based Models

4.4 Open-Loop Control

5 Results

5.1 Final PAUL version

5.2 Workspace Analysis

5.3 Performance of the Table-Based Models

5.4 Bending Experiments

5.5 Weight Carrying Experiments

6 Conclusions

Funding Information

A. Conducted Experiments and References

3.3 Manufacturing

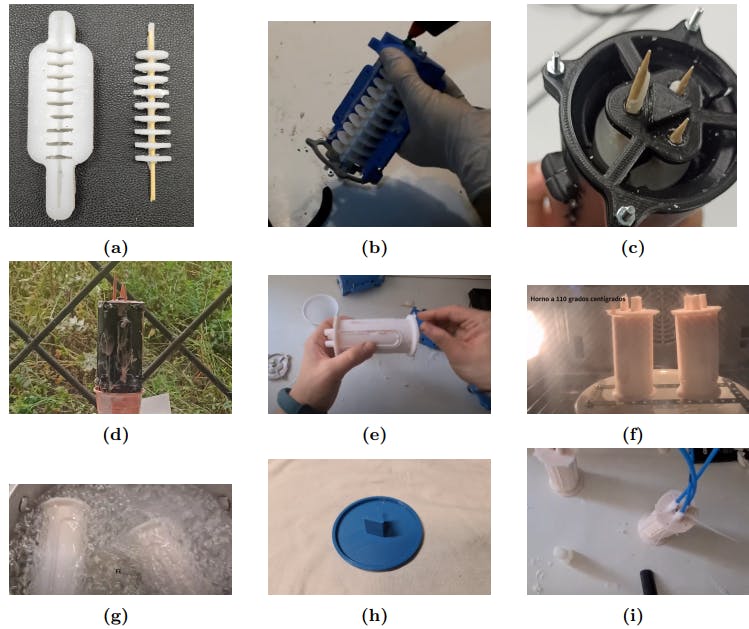

The first step in the manufacturing process is to obtain the wax cores which, when inserted into the mould, are used to create the holes for what, in the finished segment, will be the bladders. These are made by pouring paraffin wax into previously made female moulds (Figure 5a).

After half an hour, the wax has solidified and the cores can be removed and inserted into the mould (Figure 5b). The mould consists of four 3D printed parts (two sides, a bottom cap and a top grip on which the cores rest) which are screwed together and then sealed with a hot silicone bead to prevent leakage during subsequent curing (Figure 5c).

The silicone can then be poured into the mould, which must be filled to the top to counteract the aforementioned shrinkage. In particular, TinSil8015 requires a mass ratio of 10:1 liquid to catalyst. For the dimensions of the segment, about 175 g of total mixture are required.

The curing process lasts 24 hours at ambient temperature (Figure 5d), after which it can be removed from the mould. It may be necessary to use a scalpel to remove the silicone burrs (Figure 5e).

Once the segment has been built, the cores that have been used to create the bladders are removed. While the wood can be removed by pulling, it is necessary to apply heat to the segment to remove the wax. Thus, it is first placed in an oven at 110 ◦C (Figure 5f) and then immersed in a boiling water bath for 15 minutes, which ensures the elimination of the residual traces of wax (Figure 5g).

Since the males are through, it is required to close the lower part of the segment. To do this, a layer of silicone is poured onto the plate of Figure 5h, glued onto the segment and left to cure for 24 hours. Finally, the pneumatic tubes are joined to the segment, adhering them with cyanoacrylate and strengthening the tightness with the usage of plastic flanges (Figure 5i).

The final result, a functional segment is depicted in Figure 6. Experimentally, it is found that its weight is 161 g and that, as designed, it has a height of 100 mm and an external diameter of 45 mm.

3.4 Actuation Bank

Within the robot, the function of the pneumatic bench is to control the flow of compressed air from the compressor according to the control signals. Specifically, the PAUL bench consists of 6 pairs of 2/2 valves (SMC VDW20BZ1D model) and 3/2 valves (SMC Y100 model) placed in series, which will therefore allow up to 12 degrees of freedom. Both are shown in Figure 7. The physical characteristics of the 2/2 valves limited the total pressure of the assembly to 4 bar, but to reduce the risk of segment leakage, it was reduced with a flow regulator to 2 bar. Figure 8 presents a schematic of the pneumatic circuit.

The valves are operated via 24 V voltage signals. A MOSFET (model IRF540) is the switch in charge of managing them. Initially, the use of relays was considered, but the high current they would consume made their use unfeasible. An Arduino Due was chosen as the bench controller. A PC power supply, capable of supplying up to 8.5 A, is responsible for powering the unit, whose final layout is illustrated in Figure 9.