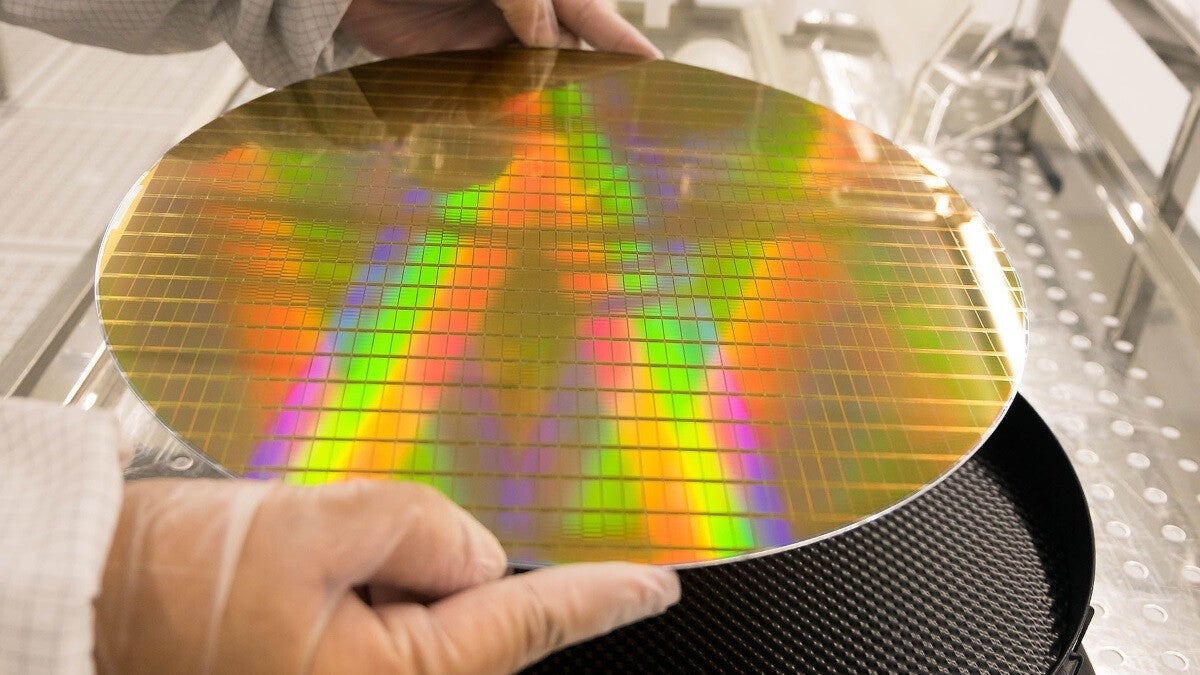

Samsung Foundry is in a serious slump. After it could not attract any big clients for its 3nm node, the foundry is having the same problem with its 2nm node. Part of the problem is that rival TSMC’s 60-70% yield at 2nm is significantly higher than the 30% yield Samsung Foundry experienced at 3nm and 2nm. The yield is the percentage of chips diced from a silicon wafer that passes quality control. Chips that don’t pass are tossed in a bin and might be used on other devices, a process known as “Binning.”

Samsung Foundry’s low yield is costing it customers. Google switched to TSMC for its Tensor G5 application processor (AP) for the Pixel 10 series. Qualcomm has decided to stick with TSMC for the powerful Snapdragon 8 Elite 2 AP instead of switching back to Samsung Foundry. Typically, the chip designer who is the client of the foundry is responsible for the costs to build the defective chips. This explains why Samsung Foundry’s market share during Q4 last year was 8.1% down from 9.1% during Q3 of 2024. TSMC’s market share in the global foundry business hit 67.1% during the fourth quarter of last year. .

TSMC’s client list reads like a Who’s Who of leading mobile device producers and suppliers including:

- Apple

- MediaTek

- Qualcomm

- Broadcom

- Google

- Nvidia

Right now, the only important Integrated Circuit (IC) on Samsung Foundry’s dance card is the Exynos 2600. This will be built on Samsung Foundry’s 2nm process node which means that Samsung could beat Apple to the market and launch the first mobile device to be powered by a 2nm application processor. Apple was the first at 5nm as the A14 Bionic powered the fourth-generation iPad Air in 2020. That was followed by the iPhone 12 series. In 2023, the iPhone 15 Pro and iPhone 15 Pro Max were the first phones to be powered by a 3nm AP, the A17 Pro.

Apple expects the A19 and A19 Pro chipsets to be produced this year by TSMC using its third-generation 3nm node (N3P). The process node numbers are important because as the numbers shrink, so does the size of the transistors placed in the chip. That means that not only can more fit inside the chip (known as the transistor count) but more can fit inside a certain area of the chip (known as transistor density). Having a higher number of transistors typically makes an AP faster and more energy efficient.

Read the latest from Alan Friedman