A wing that changes in full flight and a manufacturer who wants to reimagine the aviation of short and medium radio. Airbus prepares to test in real conditions a concept that has been maturing time in its research programs. It is not a laboratory exercise: the company has marked 2026 As a date for the first take -off of its demonstrator, an aircraft that will serve to explore if this technology can be transferred to the single corridor aircraft. The challenge is ambitious: lay the foundations of what will be the great heir of the A320.

For the manufacturer, the X-Wing is a piece within a much larger technological puzzle. The company works in disruptive engines, recyclable materials and smart platforms, and needs to decide which combinations offer more advantages. The wing capable of modifying its form is emerging as the ideal candidate to demonstrate savings in consumption and improvements in flight behavior. More than an isolated prototype, it is a test bank conceived to contrast theoretical models with data obtained in real operations.

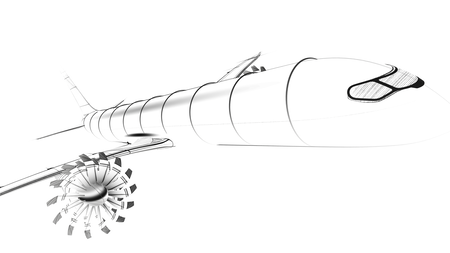

A flying laboratory to test the wing that is transformed into the air

The aeronautical builder decided to transform a citation VII into a flying laboratory. The aircraft, usually used in executive aviation, received a large -scale compound that mimics, on a reduced scale, that of a future commercial plane. To join both elements, specific transition boxes were designed, which in addition to guaranteeing structural resistance provides space for fuel and the landing system. This solution allowed to overcome the limitations of a fuselage not manufactured by Airbus and let off The demonstrator.

The demonstrator’s key is how the wing adapts to flight conditions. To prevent greater size from implying more weight, engineers incorporated a semi -eelastic hinge in the tips, capable of freeing themselves in situations of intense turbulence and thus reduce structural loads. At the same time, the back of the wing includes three flaps with small tabulators that can move independently and quickly. With this combination, the profile of the wing changes, optimizing support and reducing drag in each flight phase.

The European company wanted the demonstrator to reflect the philosophy of its line aircraft and replaced the conventional system of controls for a fly-by-wire full. All surfaces, from ailerons to rear stabilizers, are governed by electric actuators linked to control computers. The device will be handled remotely from land, without the need for crew on board, which opens margin for more demanding tests.

Before flying, the X-Wing must overcome a battery of tests on land. The European manufacturer plans structural vibration tests and alar load during this year, steps necessary to validate the design. Airbus has asked the French Civil Aviation Authority (DGAC) for the flight permit, which will allow to operate from Cazauxf, south of Bordeaux. The calendar provides shooting on the second quarter of 2026 and a first takeoff in the middle of the year, with expected flights over the Vizcaya Gulf.

Prototype en un cassna citation vii

Beyond the Ala, the Airbus roadmap includes New Generation Energy Systems and Energy Systems. Among them stands out the Open Fan, developed with CFM, which seeks an efficiency improvement of two digits and will be validated in flight with an A380 before the end of the decade. The aeronautical builder also bets on expanding the use of fuels sustainable up to 100% and for introducing hybrid architectures. The latter will use electricity in on -board tasks and further reduce the emissions of each journey.

Innovation is not limited to the wing or engine: it also reaches materials. Airbus is testing advanced thermoplastic compounds that promise to lighten the structure and, at the same time, make it more sustainable. In the face of current compounds, these can be recycled more easily and allow more agile manufacturing cycles. The MFFD project has served as a test bank, showing that it is possible to reduce weight without increasing costs. The Filton plant, in the United Kingdom, has become one of the nerve centers of this transformation.

The future plane will not be built only with more efficient wings or different motors, it will also depend on a common digital system that provides new capacities. The European company works on connected platforms capable DE Update in real timeintegrate applications and anticipate faults with predictive maintenance. Automation also will have a growing role in assistance to the pilot and in land operations. The X-Wing is, in this sense, an initial piece of a greater puzzle: demonstrate which technologies are mature and which ones should wait before making the commercial leap.

Images | Airbus

In WorldOfSoftware | Airlines have invested millions in entertainment. Passengers use it to see an plane icon slowly moving