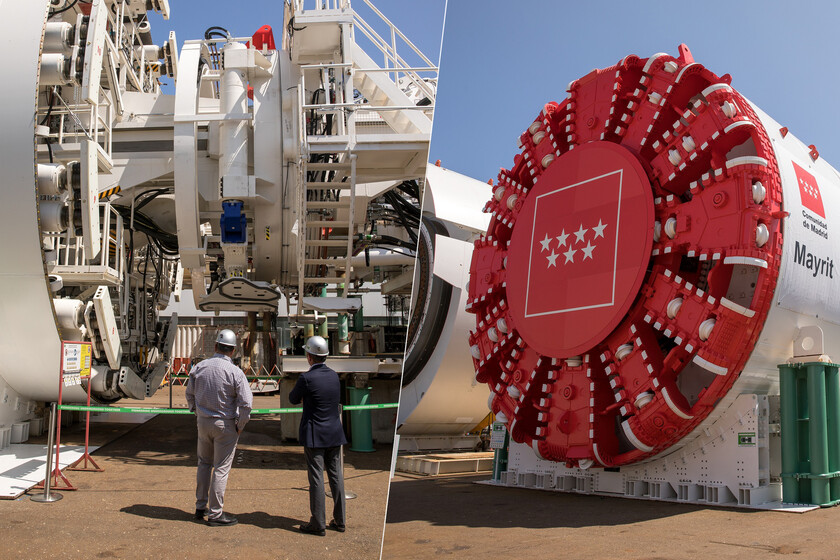

The expansion of line 11 of the Madrid Metro aspires to much more than adding stations: it wants to become a great diagonal axis that see the city transversely. It is an ambitious, complex work that demands machinery at the height of the challenge. In the center of that machinery is Mayitthe tunnelador that will be in charge of opening a passage underground. It is not a generic machine, but a model expressly designed to adapt to the geological and geotechnical conditions of the Madrid land, and that in the coming months will become the great protagonist of one of the most important developments of public transport in the capital.

A tunnelador designed for the Madrid subsoil

The tunnelador is already finished. Its manufacture has been in charge of Herrenknecht AG, one of the most recognized firms in the world in this type of machinery, and has developed in its Schwanau factory, Germany, for a 20 -month process. Mayrit is not any tunnelador. It is an EPB model (Earth Pressure Balance), adapted to excavate in cohesive land, such as those found in Madrid. It measures 98 meters long, weighs 1,500 tons and is able to advance up to 15 meters per day. On average, you can complete about 500 meters a month with teams of twelve people per shift.

To this technical level is added logistics complexity. His transfer to Madrid will not be fast or simple. The machine must be completely dismantled, piece by piece, for the next three months. Then, one will begin trip more than 2,000 kilometers which will combine road journeys to Antwerp, maritime transport to the port of Santander and, from there, its truck transfer to the future Comillas station, in Carabanchel. There will begin the reverse process: a new assembly that will last until March 2026, when it is planned to start operating.

Its function will be to drill the section of the section between Elliptical Plaza and Count de Casal, one of the most complex phases of the expansion. The works in this section are already at 18.4% execution, and the regional government has announced an investment of 518 million euros only at this stage. In parallel, manual excavation works have already begun in a 700 -meter stretch between quotes and elliptical square, with a rhythm of progress of about 50 meters per month. The goal: to leave the ground prepared for when Mayrit enters action.

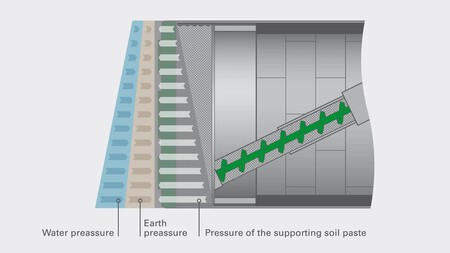

And the truth is that, beyond rhetoric, the technology that moves Mayrit is far from being trivial. Inside, an endless screw transports the material excavated to a tape, while pressure sensors allow Real time control the balance of forces in the excavation chamber. This allows to maintain the stability of the front and avoid sinking, even in heterogeneous terrain with the presence of gravel, water or sand.

In addition, the system can be adapted on the march to different geological scenarios. Herrenknecht has developed several solutions that convert the end of the endless into a wash circuit to also work with sludge when the land demands. Other modules allow to modify the consistency of the soil by injections of bentonite, water or foam. At the moment, the arrival of Mayrit to Madrid is scheduled for December.

Images | Madrid Metro | Herrenknecht

In WorldOfSoftware | The largest concrete wall in Spain is in Salamanca and generates electricity: this is the almond dam