A single mishap in inventory operations can create a ripple effect across your business.

Let’s say you forecast a sales demand for 1000 units of a product, but the actual demand is 2000 units. The result? Stockouts, unsatisfied customers, increased shipping costs, loss of revenue, and other operational inefficiencies.

This is why you must track the right inventory metrics and key performance indicators (KPIs) to maintain a balance of stocks, reduce operating costs and errors, and improve overall inventory management process efficiency.

In this comprehensive guide, we’ll explain the key metrics you must track to ensure seamless inventory operations and provide the steps to monitor KPIs effectively.

⏰ 60-Second Summary

- Poor inventory management causes stockouts, customer dissatisfaction, and revenue loss

- Tracking inventory metrics/KPIs is essential for maintaining optimal stock levels and efficiency

- Key metric categories include Sales, Receiving, Operations, Employee performance, and other important metrics like shrinkage and backorder rates

- KPI selection should be relevant to business goals, provide actionable insights, and align with industry specifics

- Effective KPI implementation involves setting SMART goals and focusing on metrics that answer key business questions

- Avoid vanity metrics and track trends over time for deeper insights into inventory performance

Understanding Inventory Management KPIs

Inventory management KPIs are quantifiable metrics that evaluate inventory management effectiveness. They help you monitor and analyze inventory levels, turnover rates, and overall inventory health to achieve your business objectives.

Tracking inventory management metrics and KPIs also helps control inventory costs, forecast customer demand, and ensure operational efficiency.

For instance, you can analyze inventory holding costs to identify the costs associated with inventory storage and take action if the costs are too high.

Benefits of Inventory KPI and Metrics Tracking

KPIs and metrics are like crystal balls. They help you predict and prevent.

Once you start tracking KPIs, you’ll know what’s working well and what’s not. Here are a few benefits of tracking inventory metrics and KPIs.

🌟 Improved customer satisfaction score

Suppose your customer satisfaction score is 70%, which is a decline from the last quarter due to frequent stockouts. Track KPIs like fill rate, lead time, inventory turnover, safety stock levels, and stock-to-sales ratio to prevent understocking and create a buffer for unexpected demand surges. As a result, you can offer a hassle-free customer experience, increasing the overall satisfaction score.

📊 Enhanced service level and reduction in stockouts

Tracking inventory metrics shows how good your services are. For example, if your fill and perfect order rates are above 95%, know that you aced the service game. Your deliveries are on time, there’s always sufficient inventory, and customer complaints have reduced significantly.

🎯 Better inventory accuracy and efficiency

Inventory KPIs improve overall efficiency and ensure accurate demand forecasts by highlighting areas of improvement.

For example, if you have a low inventory turnover ratio, it might mean poor purchasing practices, overstocking, changing customer demands, or faulty decision-making. Thus, you can track demand forecasting accuracy, assess your inventory purchases, and implement best practices to prevent overstocking.

🧠 Did you know? Walmart identified its supply chain delays by tracking its current inventory levels and turnover rates. This helped the company switch to a vendor-managed inventory model that minimized delays in inventory movement and reduced the time-to-receive metric.

Key Inventory Metrics to Track

Let’s look at the different types of inventory metrics you should track for informed decision-making.

🌱 Inventory metrics: Sales KPIs

Sales KPIs show how quickly your inventory turns into sales. They act as a checkpoint, helping you determine if your stock is aligned with what customers want, product pricing is right, and you have optimum inventory levels.

Essentially, they tell you whether your inventory is helping you hit your sales goals or holding you back. Here are the top sales KPIs to help your sales monitor your sales goals:

Inventory turnover rate

The inventory turnover rate measures the number of times inventory is sold and replaced over a specific period. Think of it as a way to check whether your products are clearing out quickly or just sitting there collecting dust.

It determines how much of the company stock is selling and whether there’s too much inventory compared to sales. The metric also helps identify slow-moving products, allowing you to optimize inventory levels.

Inventory Turnover Rate = Cost of Goods Sold (COGS) / Average Inventory

Note: COGS is the direct cost of producing goods/services. It includes material and labor costs, and direct factory overheads.

📌 Example: if your COGS is $300,000 and the inventory at the start and end of a year are $100,000 and $8,000 respectively, your inventory turnover rate is [ $300,000 / (100,000 + 8000) / 2 ] = 5.55

Use ’s Cost Analysis Template to get a detailed view of your material, labor, and other direct costs so you can identify unnecessary costs and areas of potential savings.

Sell-through rate

The sell-through rate calculates the percentage of inventory sold compared to the inventory received. For example, if your sell-through rate is 70%, it means you sold 70 out of every 100 units of a product.

A high sell-through rate usually means your products are in demand, while a low rate could be a sign to rethink your stock or marketing strategy. It can help you identify the most popular and underperforming products and make informed purchase decisions.

Sell-through Rate = (Number of Units Sold / Number of Units Received) x 100

Gross margin by product

Gross margin by product shows you how much profit you make on each item after covering its production costs. Basically, it’s the difference between the selling price of a product and what it costs you to make.

So, if you sell a product for $100 and the production cost is $60, your gross margin is $40. It’s a straightforward way to see how well each product is doing. It helps you identify the most profitable products, build pricing strategies, and optimize the product mix.

Gross Margin by Product = (Sales Revenue – COGS / Sales Revenue) x 100

📌 Example: If your sales revenue from a specific product type is $10,000 and its COGS is $2000, your gross margin by product is [(10000-2000) / 10000 ] x 100 = 80%.

Leverage the Sales Tracker Template to track the gross profit margin of each product unit. You can set and review sales targets, track product performance, measure profits, and make data-driven sales and operations decisions.

Revenue per unit

Revenue per unit is all about figuring out how much money each product brings in on average over a certain period. It gives you a clear picture of how well each item is performing and what it contributes to your overall sales.

For example, if you sell a product for $50 and you’ve sold 100 units in a month, your revenue per unit is $50. This metric helps you spot your top performers and understand where you might want to focus your sales efforts for better profitability!

Revenue Per Unit = Total Revenue / Total Units Sold

📌 Example: You can use revenue per unit to calculate the revenue generated by each pricing tier—basic, professional, and enterprise in a month.

| Subscription Tiers | Total subscribers | Total monthly revenue ($) | Revenue per unit per month ($) |

| Basic | 7000 | 42,000 | 6 |

| Professional | 5000 | 25,000 | 5 |

| Enterprise | 3000 | 24,000 | 8 |

The Enterprise level generates the highest revenue per unit despite having the lowest number of subscribers. This indicates how well the premium pricing strategy is working. Thus, you can break the value of each pricing tier and make strategic decisions about pricing, customer targeting, promotional offers, and more.

🌱 Inventory metrics: Receiving KPIs

Inventory receiving KPIs help you evaluate how effectively you manage the process of bringing in new stock. They provide insights into how you handle incoming inventory, which can significantly affect your overall operational performance.

Time to receive

Time to receive measures the time the team takes to prepare the incoming stock for sales. It evaluates the efficiency of your stock-receiving process. A shorter receiving time implies faster inventory availability, lower warehouse holding costs, and improved operational efficiency.

Time to Receive = Total Time From Inventory Arrival to Inventory Ready for Sale (Stock Validation Time + Time to Record Stock + Time to Prep Stock for Sales)

📌 Example: Suppose inventory arrives at 9:00 AM. Unloading begins at 9:05 AM, and stock verification and quality check are done at 11:00 AM. Then, inventory is labeled and ready for sale at 11.30 AM. Total time = 9.00 AM to 11.30 AM = 1.5 hours.

Put away time

The put away time calculates the time taken to move the inventory from the receiving area and store it in its final warehouse space. When products are stored quickly and correctly, it reduces the chances of misplacing items and provides more receiving area for new stock.

Put Away Time = Total Time Taken From Receiving Inventory to Moving It to the Storage Location

📌 Example: If you receive inventory at 10:00 AM and move it to the storage at 11:30 AM, your put away time will be 1.5 hours.

Try Time Tracking to easily monitor and analyze the time spent on inventory activities like storage, quality check, and stock recording and improve operational efficiency.

🌱 Inventory Metrics: Operational KPIs

Operational KPIs tell you how well your inventory processes are running. It helps you measure their efficiency and improve as needed.

Stock to sales ratio

The stock-to-sales ratio measures the relationship between the value of inventory at hand and the sales made during a specific period. It helps you understand how efficiently your inventory converts to sales.

If your stock-to-sales ratio is low, you aren’t holding enough inventory to meet customer demands. On the other hand, if the ratio is high, it might hint at overstocking and increasing holding costs.

Stock to Sales Ratio = Total Inventory Value at the End of a Period / Total Sales for the Period

📌 Example: If your total inventory value at the end of a year is $4000 and the total sales for the year is $10,000, your stock-to-sales ratio will be 4000/10000 = 0.4 or 40%

Order cycle time

The order cycle time measures how long it takes to fulfill a customer order. It evaluates the efficiency of your internal processes, including dispatch, shipping readiness, and delivery.

Similarly, you can also use this metric to measure the time it takes to receive an order from the supplier. This metric reflects the efficiency of the ordering process and helps identify supply chain issues.

Order Cycle Time = (Order Delivery Date – Date of Order Placed) / Total Orders Shipped

📌 Example: If your order date is 1st January 2025 and delivery date is 31st January 2025 and total orders shipped is 6000 units, the order cycle time will be 31 / 6000 = 0.00517 days x 24 x 60 = 7.44 minutes.

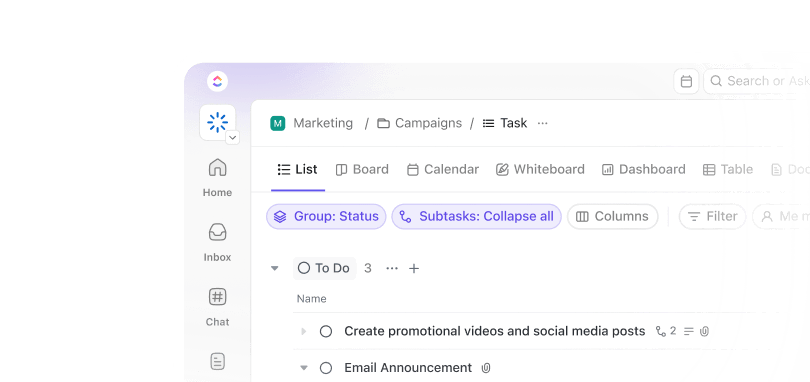

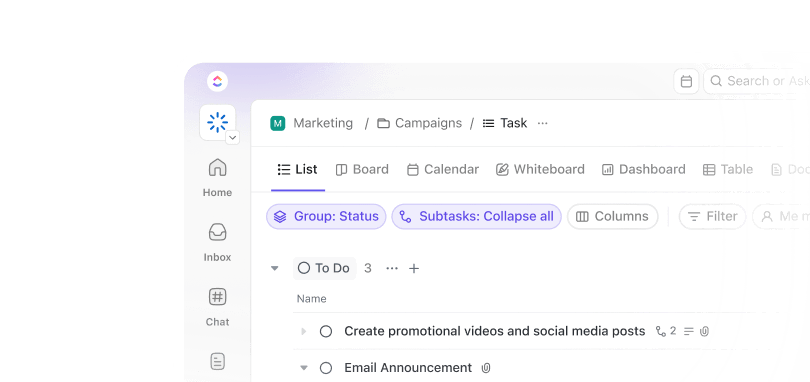

Custom Fields and Custom Statuses can help you streamline inventory processes. You can use Custom Fields to capture order details such as ID, dates of delivery and order placed, order specifications, suppliers, etc. Custom Statuses, such as ‘On hold,’ ‘New order,’ and ‘Delivered’ enable you to track the real-time progress of any order.

Fill rate

The fill rate metric measures the percentage of customer orders fulfilled completely from existing inventory, without stockouts or backorders.

This inventory performance metric measures the effectiveness of your processes, identifies inventory availability issues, and helps manage stock replenishment strategies. A high fill rate indicates that you have the right products available when customers want them, while a low fill rate signals potential inventory availability issues.

Fill Rate = (Number of Orders Fulfilled Completely / Total Number of Orders) X 100

📌 Example: If the number of orders fulfilled is 10,000 and the total number of orders is 12,000, your fill rate is (10,000 / 12,000) x 100 = 83%.

Note: A good fill rate is typically between 85 to 95%. However, high-performing brands aim to achieve a fill rate above 95%.

Lead time

Lead time measures the total time between placing an order and receiving it. You can use this metric to measure the time taken to fulfill a customer order and to receive inventory from suppliers after placing an order.

This inventory metric helps in aggregate planning, demand forecasting, and improving supply chain efficiency.

Lead Time = Procurement Time + Order Processing Time + Delivery Time

Or

Lead Time = Order Delivery Date – Order Placed Date

📌 Example: If you take a total of 15 days to process and fulfill a customer’s order, you can assess your internal processes to reduce the lead time. Optimize inventory management, get insights into the supply chain, and make strategic purchase and sales decisions.

🌱 Inventory metrics: Employee KPIs

Unlike the other inventory metrics, these KPIs measure employee productivity and performance. The higher the productivity, the better the overall business performance.

Labor cost per item

The labor cost per item calculates the amount spent on producing one unit of a product. It includes labor wages and additional production costs incurred throughout the production-to-sell process.

Measuring labor cost per item will help you cut down on unnecessary expenses, set competitive product prices, and implement processes to reduce labor costs.

Labor Cost per Item = Total Labor Cost / Number of Total Units

📌 Example: If your total labor cost is $10,000 a month to produce 500 units, your labor cost is $10,000 / 500 = $20.

Internal Warehouse Management System (WMS) efficiency

The WMS efficiency metric measures the ROI (return on investment) for your internal inventory management software. It calculates the profit or loss incurred from purchasing the warehouse management system.

This metric considers the cost of the software, additional hardware costs, unrealized gains (for example, time saved in stock recording), and new opportunities (for example, catering to more customers than before). Using this metric, you can:

- Assess whether the WMS yields satisfactory outcomes or not

- Identify areas and warehouse processes for optimization

- Make informed decisions about tech investments

Internal WMS Efficiency = (Gain on Investment – Cost on Investment) / Cost on Investment

📌 Example: If your gain and cost on investment is $5000 and $10000, respectively, your WMS efficiency is [(15000 – 10000) / 10000] x 100 = 50%.

Use ’s Table View to visualize WMS gains and costs in a spreadsheet-like format and easily calculate WMS efficiency. You can also organize WMS efficiency metrics in tables to assess its results, identify potential issues, and make data-driven decisions.

🌱 Additional important inventory management KPIs

Here are a few more inventory metrics KPI examples to help you get a deeper understanding of your inventory performance.

Days on hand / Weeks on hand

The days and weeks on hand inventory metrics measure the number of days and weeks the existing inventory will last. In other words, they calculate the days/weeks a business takes to sell its inventory.

Days on Hand = (Average Inventory/ Cost of Sales) x 365

Weeks on Hand = (Average Inventory/ Cost of Sales) x 52

📌 Example: If your average inventory is $10,000 and the cost of sales is $2000 the days and weeks on hand will be 1825 days and 260 weeks, respectively.

Backorder rate

This inventory metric shows the percentage of customer orders that cannot be fulfilled immediately from the existing inventory. This metric shows how well you manage stocks in demand and your demand and supply alignment.

Backorder Rate = (Number of Products on Backorder / Total Number of Orders) X 100

📌 Example: If you have 500 products on backorder and the total number of orders is 10000, your backorder rate is 5%.

Accuracy of forecast demand

The demand forecast accuracy compares the actual on-hand inventory with the forecast to verify its accuracy.

Accuracy of Forecast Demand = [{Actual – (Actual – Forecast)} / Actual] x 100

📌 Example: If your forecasted demand is that of 10,000 units and actual sales stand at 9000 units. Then, your demand forecast accuracy would be [10,000 – (10,000 – 9000)] / 10,000 = 0.9 x 100 = 90% accurate.

Rate of return / Lost sales ratio

The rate of return is the percentage of sold products returned by customers. This metric helps you gauge customer satisfaction with products.

Rate of Return = (Number of Products Returned / Total Products Sold) X 100

📌 Example: If customers return 500 products out of 10,000 products sold, your rate of return is 5%.

On the other hand, the lost sales ratio measures the potential sales you fail to achieve due to stockouts. This metric helps you understand the effectiveness of your inventory management processes and their impact on revenue.

Lost Sales Ratio = (Number of Days of Product Stockout / 365) X 100

📌 Example: If your days of stockout is 20, the lost sales ratio is 5.45.

Perfect order rate / Inventory shrinkage

The perfect order rate calculates the percentage of orders fulfilled perfectly without any issues or errors.

Perfect Order Rate = (Number of Perfect Orders / Total Number of Orders) x 100

📌 Example: If you fulfill 5000 orders perfectly out of 8000 orders, your perfect order rate is 62.5%.

The inventory shrinkage metric shows the loss of inventory due to damage, loss in transit, theft, or other errors. This metric highlights issues with your inventory accuracy and logistics processes.

Inventory Shrinkage = [(Recorded Inventory − Actual Inventory) / Recorded Inventory] × 100

📌 Example: If your recorded inventory is $80,000 and the actual is $75000, your shrinkage rate is 6.25%.

Other Factors and Metrics in Inventory Management

Here are a few more factors and inventory management metrics to add to your KPI dashboard.

Cost per unit and Average inventory

Cost per unit calculates the total cost incurred in producing one unit of a product. This metric is crucial for companies manufacturing products in larger quantities.

Cost per Unit = (Fixed Costs + Variable Costs) / Number of Units Produced

📌 Example: If the fixed and variable costs incurred are $500 and $300, respectively, and the number of units is 1000, the cost per unit is (500 + 3000) / 1000 = $3.5.

Average inventory, on the other hand, is a metric to estimate the value of inventory you have over a specific period.

Average Inventory = (Inventory at the Start of a Period + Inventory Value at the End of a Period) / 2

📌 Example: If the inventory value at the start of a period is $4000 and at the end of the period is $500, the average inventory will be $2250.

Inventory carrying cost

Inventory carrying cost is the total cost incurred in holding the inventory in a warehouse or storage until it is sold off. This metric typically includes capital, storage, inventory service, and inventory risk costs.

Tracking this metric helps you identify hidden inventory expenses and unnecessary holding costs, and guides inventory planning strategies.

Inventory Carrying Cost = [(Storage Costs + Insurance Costs + Opportunity Costs + Service Costs) / Total Inventory Value] x 100

📌 Example: If your storage cost is $500, service cost is $200, insurance cost is $300, and the total inventory value is $20,000, your carrying cost of inventory as a percentage is (500 + 300 + 200) / 20,000 ] x 100 = 5%.

Gross margin return on investment

The gross margin ROI measures how much a company earns compared to the amount of inventory purchased. This metric shows your efficiency in buying and selling products.

Gross Margin Return on Investment = (Gross Margin / Average Inventory Cost) X 100

📌 Example: If your gross margin is $2000 and the average inventory cost is $10,000, your gross margin ROI is 20%.

How to Choose the Right Inventory Management KPIs?

Just like you can’t ensure project success by focusing only on a single resource or skill, effective inventory management requires a balanced selection of KPIs.

Here’s how you can choose the right inventory management metrics and KPIs.

Factors to consider when selecting KPIs

Consider the following factors when choosing inventory metrics and KPIs:

🚀 Relevance to business goals

Choose KPIs related to your company’s strategic objectives. This ensures tracking metrics that contribute to improving business performance.

For instance, if your goal is to improve customer satisfaction, track order cycle time (the time between an order placed and delivered). A shorter cycle time will help you improve customer satisfaction.

💡 Actionable insights

Choose inventory metrics and KPIs that provide actionable insights and help you improve. Make sure to choose metrics that highlight areas that need attention.

For example, tracking the stock-to-sales ratio shows how much inventory is available for sale. This metric can help you identify overstocking issues and also prevent stockouts.

📑 Industry requirements

Consider industry requirements when selecting inventory KPIs. For example, revenue per unit can help you analyze and create pricing strategies if you’re a subscription-based business.

Similarly, if you’re an automotive company, tracking metrics like supplier lead time is vital for timely production.

Aligning KPIs with business goals

In addition to the above factors, ensure your KPIs align with your business goals. Here’s how you can align them.

Step 1: Set SMART business goals

SMART goals offer a clear framework for setting and achieving objectives, ensuring that your inventory goals are actionable. This focus allows you to work effectively toward improving your overall inventory operations.

So, define your business goals before selecting KPIs. It ensures that your KPIs directly support your objectives

Here are a few examples of SMART goals:

- Reduce the product return rate by 10% within the next quarter to improve brand reputation

- Reduce stockouts on high-demand items by 15% within the next quarter to improve customer satisfaction score

Use Goals to set your business goals and automate progress tracking. You can organize your goals in one place, map KPIs, track targets, and more.

💡Pro Tip: Use goal-setting templates to set SMART goals and targets in an organized way. These templates let you visualize your goals, track progress, and manage them in one place.

Step 2: List business questions

When choosing inventory KPIs, list the business questions you want answers to and make sure the KPIs answer these listed questions. For instance:

- Why are we facing delivery delays?

- Why are there frequent stockouts?

- How much is the current rate of return?

Then, choose KPIs that answer the above questions—stockout rate, lead time, order cycle time, rate of return, etc. Monitoring these KPIs consistently will help you identify the reasons behind operational inefficiencies.

Step 3: Stop chasing vanity metrics

Vanity metrics are KPIs that look great but don’t provide actionable insights to guide your decision-making. For instance, total inventory value is a vanity metric as it doesn’t reflect the efficiency of inventory management. Moreover, it can mask slow-moving items and overstocking issues.

Step 4: Track trends

Monitor your inventory KPI trends over months and years to get deeper insights into your business performance. For example, if you see a declining inventory turnover rate, it might indicate slow selling. You can further dig deeper to find out if it’s due to overstocking, ineffective marketing strategies, or changes in customer demands.

How to Track Inventory Management KPIs?

Tracking inventory management KPIs is a lot of work, as we can see. You need to define business goals, set clear KPIs, thresholds, and benchmarks, create dashboards, and more. So, the easy way out is to implement KPI software.

is the everything app for work with robust KPI-tracking capabilities. It not only manages project management resources but offers a wide array of features to define and track KPIs, set targets, monitor progress, manage tasks, and collaborate across multiple teams.

Leverage Dashboards to monitor KPIs in real time. Organize your most relevant KPIs in one place, and use charts, graphs, and progress bars to quickly see where you stand against specific targets.

These custom dashboards help you visualize data for easy understanding, identify problem areas, and act promptly. Moreover, they guide your decision-making and ensure transparency across teams and stakeholders.

Ready to step it up a little? Brain, ’s built-in AI assistant, makes working with KPIs easier. It can suggest KPIs you should be tracking, help you define them clearly, and then pull all the necessary info from your workspace (like tasks, Custom Fields, and time tracking) to actually calculate them.

Then, it gets to work analyzing the data, spotting trends and weird outliers, and even figuring out what the data means. You can literally ask questions like “How did we do on this KPI last month?” and it’ll give you answers based on the numbers. Plus, it helps you create reports and put everything on dashboards so you can see your progress at a glance!

That’s not all. You can also utilize ’s Templates to jump-start your inventory processes. ’s inventory templates come with a pre-built framework to help you track essentials, maintain stock records and vendor lists, automate reporting, monitor and analyze metrics, and more.

For instance, the Inventory Management Template has everything you need to organize, track, and update inventory data. Moreover, this template automates inventory tracking and makes it easier to stay updated. You can also set automatic alerts for reorders.

Using this template, you can:

- Track inventory levels, stock availability, and movement

- Record pricing with product images in a database

- Analyze inventory trends to make informed decisions

- Identify unnecessary costs, sources of wastage, and lost sales

🍭 Bonus: Use ’s Project Metrics Template to create a seamless quality check process for your deliverables. This template will help you identify areas for improvement and ensure a reduction in the rate of return.

Additionally, ’s KPI Template enables tracking all your success metrics in one place. You can view your team’s progress toward the set goals, track performance, and ensure everyone’s on the same page.

That said, implementing the right inventory management software isn’t enough. There are a few steps and best practices for effectively monitoring inventory metrics.

Implementing inventory metrics best practices

Here are the steps to effectively implement and monitor inventory KPIs.

🙌 Use the right tool: Create an inventory management system with the right software to organize and track inventory data and report on selected KPIs

🙌 Train teams: Make sure your team understands and uses the software to its full potential. Conduct training sessions, take feedback, and calculate system ROI to assess the gains and losses

🙌 Review and adjust KPIs: Track KPIs and keep adjusting strategies based on findings. For example, you might feel that your inventory turnover goal is unrealistic after a performance review. So, make adjustments accordingly

Besides implementing the best practices, beware of these common challenges in KPI tracking.

⚠️ Inconsistency: Tracking KPIs consistently is a challenge. Establish a routine to track the metrics regularly or use automated inventory tracking system to maintain consistency

⚠️ Limited data visibility: Companies often struggle to get a comprehensive view of data across teams and warehouses. Use centralized inventory management systems to view data in one place and maintain transparency across teams

⚠️ Overly complex metrics: Using too many or overly complex KPIs can overwhelm teams and obscure actionable insights. Focus on a few key, actionable KPIs that align closely with business goals

💡Pro Tip: ’s collaborative inventory templates let you manage inventory across multiple warehouses. They provide a centralized view of all data and make tracking product locations, stock levels, etc., easier.

Simplifying Inventory Metrics and KPIs Tracking With

Tracking KPIs is essential to keep your inventory’s health and performance in check. However, inconsistent data and the lack of effective tools can result in inaccurate metrics.

This is where you need as your inventory management solution. With , you can easily set inventory management objectives, do effective inventory planning, create your own KPI dashboards, collaborate with teams, ensure accurate documentation, maintain inventory records, automate inventory reporting, and whatnot.

Plus, you get a plethora of free templates to standardize inventory tracking processes and reduce errors.

So, what are you waiting for? Sign up for free to explore features now and improve inventory efficiency!

Everything you need to stay organized and get work done.

/cdn.vox-cdn.com/uploads/chorus_asset/file/24000091/acastro_STK075_03.jpg)