What happens when you lose track of the small things in your supply chain?

📦 A late shipment here, an inventory miscalculation there—before you know it, customer complaints pile up, costs rise, and productivity takes a hit. Managing a supply chain is complex, but the real challenge lies in knowing what to measure and how to optimize performance.

That’s where supply chain KPIs helps you:

✅ Identify inefficiencies before they snowball into bigger problems

✅ Optimize processes to cut costs and improve fulfillment times

✅ Enhance customer satisfaction by ensuring seamless deliveries

In this article, we’ll explore the most critical supply chain KPIs, why they matter, and how tracking them can help you deliver better results—faster and smarter.

Top Supply Chain KPIs and Metrics to Track

⏰ 60-Second Summary

- Supply chain KPIs are measurable metrics that measure supply chain efficiency and performance

- KPIs can be categorized into operational, financial, and customer service metrics

- Key supply chain metrics include order accuracy, on-time delivery, inventory turnover, fill rate, and cash-to-cash cycle time. These KPIs help businesses identify bottlenecks, reduce delays, and improve supply chain performance

- Choosing the right KPIs requires aligning them with business goals, focusing on actionable metrics, and using industry benchmarks

- To effectively implement KPIs, businesses should set clear targets, track metrics using real-time data, and continuously analyze performance

- Use KPI setting and tracking software like to set smart goals, get real-time supply chain insights, and automate processes to achieve supply chain KPIs

Understanding Supply Chain KPIs

Supply chain key performance indicators (KPIs) are measurable metrics that measure supply chain efficiency, reliability, and alignment with business goals.

📌 For example:

- Supplier on-time delivery rate: Measures how reliably suppliers meet deadlines

- Order fulfillment time: Tracks how quickly orders are processed from placement to delivery

- Inventory accuracy: Ensures stock levels align with actual inventory, reducing waste or shortages

Categories of supply chain KPIs

Supply chain KPIs fall into three categories:

- 📦 Operational: Metrics like order fulfillment cycle time and inventory turnover ratio track efficiency and supply chain process effectiveness

- 💵 Financial: Indicators such as cost of goods sold (COGS) and transportation costs focus on cost management and profitability

- 🚚 Customer-focused: Metrics like on-time delivery rate and perfect order rate gauge customer satisfaction and delivery performance

These categories work together to ensure a comprehensive view of supply chain health.

How supply chain KPIs relate to enterprise resource planning (ERP)

KPIs work hand-in-hand with ERP systems. Think of ERP platforms as the central hub that connects data across your departments, allowing you to measure supply chain performance in real time and turn those insights into meaningful actions.

Essential Supply Chain KPIs

We’ve picked the top supply chain KPIs you can track; here are those:

Perfect Order Rate

The Perfect Order Rate (POR) measures the percentage of error-free orders delivered from start to finish. This means every step of the process, from order placement to picking, packing, shipping, and delivery, is completed flawlessly. No delays, no damage, no incorrect items, and no missed documentation. It’s a gold standard for customer satisfaction, inventory planning, and supply chain efficiency.

Perfect Order Rate (%) = (Number of Perfect Orders / Total Number of Orders) × 100

Achieving a high perfect order rate directly reflects how well your warehouse operations are running. When everything in the warehouse functions smoothly—accurate inventory management, precise order picking, and efficient packing processes, it reduces errors and ensures that orders meet customer demand.

🚀 How to improve POR:

- Use automated inventory and order management systems

- Implement barcode scanning to reduce picking and packing errors

- Regularly audit and optimize warehouse workflows

💡Pro Tip: Even a 1% drop in POR can lead to lost customers. Prioritize error reduction across every stage of order fulfillment.

Cash-to-Cash Cycle time

The Cash-to-Cash Cycle time (C2C) measures how long it takes to turn cash spent on inventory into revenue from sales. It tracks the time between paying suppliers and receiving payments from customers. A shorter C2C means better efficiency and liquidity.

By optimizing C2C, you can enhance liquidity and working capital, ensuring smooth financial operations and stronger supplier relationships.

C2C (Days) = DIO + DSO − DPO

Where:

- DIO: Days Inventory Outstanding

- DSO: Days Sales Outstanding

- DPO: Days Payable Outstanding

Accounts payable (AP) plays a big role in how long a company takes to pay its bills. When managed well, it allows businesses to extend payment terms without facing late fees. Plus, logistics software can help free up cash, improve cash flow, and make negotiating better deals with suppliers easier. It’s all about keeping your finances flexible and your relationships strong!

🚀 How to improve C2C:

- Use automated inventory and order management systems

- Implement barcode scanning to reduce errors

- Regularly audit and optimize warehouse workflows

Customer Order Cycle Time

Customer Order Cycle Time (COCT) measures the total time taken to fulfill a customer order—from when it is placed to when it is delivered. It highlights the efficiency of your order management and fulfillment processes and directly impacts customer satisfaction.

A shorter supply chain cycle time often leads to higher customer satisfaction and repeat business.

Customer Order Cycle Time (Days) = Order Delivery Date − Order Placement Date

🚀 How to improve COCT:

- Use automated order management systems

- Optimize picking, packing, and shipping processes

- Track and address delivery bottlenecks

💡Pro Tip: Customer order cycle time (COCT) plays a big role in meeting service-level agreements (SLAs) and is a key procurement KPI. It shows whether you’re keeping your delivery promises.

Fill Rate

Fill Rate shows how well you fulfill customer orders from your current stock. It’s a simple yet powerful metric that reflects how effectively your inventory meets demand.

Fill Rate is closely tied to stockouts and inventory management. A low fill rate often points to stockouts, leading to missed sales and unhappy customers. Good inventory management, like accurate forecasting and timely restocking, is key to keeping fill rates high.

Fill Rate (%) = (Items Delivered on Time / Total Items Ordered) ×100

🚀 How to improve fill rate:

- Use accurate demand forecasting

- Implement timely restocking processes

- Optimize inventory management systems

🧠 Did you know? When you maintain the right stock levels, you reduce stockouts and keep customers satisfied and loyal. A high fill rate shows you’re efficient and committed to meeting customer expectations and needs.

Inventory Days of Supply

Inventory Days of Supply (IDS) measures how many days your current inventory can last based on average daily usage or sales. It’s a critical metric for balancing stock levels with demand, ensuring you’re neither overstocked nor running out of key products.

To optimize IDS, you should use historical data to spot trends and account for seasonality. Plus, real-time analytics, like current orders and market shifts, help fine-tune forecasts. Teamwork across sales, marketing, and supply chain ensures everyone’s on the same page.

IDS (Days) = Current Inventory / Average Daily Usage

🚀 How to improve IDS:

- Use historical data to improve demand forecasts

- Monitor real-time analytics for market shifts

- Align inventory planning with sales and marketing teams

💡Pro Tip: Monitor your forecasting accuracy regularly and adjust based on actual demand patterns to continuously improve your inventory management efficiency.

Freight Bill Accuracy

Freight Bill Accuracy ensures your freight invoices match the agreed rates, services, and shipment details. When your bills are accurate, you avoid overpayments, disputes, and unnecessary headaches in your logistics process.

Correct freight bills keep your supply chain logistics running smoothly. Mistakes can lead to higher costs, payment delays, and damaged carrier relationships. In LTL shipping, where shipments share space and costs depend on weight, dimensions, and extra services, billing errors can quickly pile up.

Freight Bill Accuracy (%) = (Total Number of Freight Bills / Number of Accurate Freight Bills) × 100

🚀 How to improve Freight Bill Accuracy:

- Use automated freight auditing systems

- Validate shipment details before invoicing

- Regularly review and reconcile carrier contracts

Days Sales Outstanding

Days Sales Outstanding (DSO) measures the average number of days it takes for a business to collect payments after a sale. It’s a key indicator of how efficiently a company manages its accounts receivable.

A lower DSO means faster collections and healthier cash flow, which allows businesses to reinvest in operations and reduce reliance on external financing. Conversely, a high DSO indicates payment delays, tying up cash and increasing the risk of bad debts.

DSO (Days) = (Total Credit Sales / Accounts Receivable) × Number of Days

🚀 How to improve DSO:

- Set clear payment terms and policies

- Use automated invoicing and payment systems

- Implement proactive collections processes

Inventory Turnover

Inventory Turnover tracks how often a business sells and replenishes its inventory over time, reflecting stock management efficiency.

A high Inventory Turnover rate shows efficient inventory management and strong sales but could risk stockouts. Low turnover suggests overstocking or slow sales, increasing holding costs.

Inventory Turnover = Cost of Goods Sold (COGS) / Average Inventory

🚀 How to improve Inventory Turnover:

- Refine demand forecasting accuracy

- Streamline reordering and restocking processes

- Optimize stock levels to match demand

Gross Margin Return on Investment

Gross Margin Return on Investment (GMROI) measures inventory profitability by evaluating a business’s gross profit margin for every dollar invested in inventory. It highlights the financial efficiency of inventory management.

GMROI also helps pinpoint your most profitable items and optimize inventory for better results. Regular tracking lets you fine-tune pricing, manage stock smarter, and focus on high-margin products, ensuring sustainable profitability.

GMROI = Gross Margin / Average Inventory Cost

Where gross margin is the difference between sales revenue and the cost of goods sold (COGS). A high GMROI means your inventory earns strong returns, while a low GMROI signals inefficiencies like overstocking or low-margin products.

🚀 How to improve GMROI:

- Focus on high-margin products

- Optimize inventory levels to reduce holding costs

- Regularly review and adjust pricing strategies

Inventory Velocity

Inventory Velocity tracks how quickly inventory moves through the supply chain, from purchase to sale. It shows how efficiently you’re managing stock and meeting demand. Faster inventory velocity lowers holding costs and improves cash flow, directly impacting cogs. Quick turnover means less money in storage and a reduced risk of outdated products.

Inventory velocity also helps shape pricing strategies. High-velocity items can handle lower margins due to higher volume sales, while slow-moving items might need discounts or promotions to clear stock.

Inventory Velocity = Cost of goods sold (COGS) / Average Inventory Cost

🚀 How to improve Inventory Velocity:

- Improve demand forecasting to match stock with sales

- Streamline procurement and restocking processes

- Use promotions or discounts to clear slow-moving stock

Best Practices for Selecting the Right KPIs

Choosing the right KPIs for your supply chain can feel overwhelming, but it doesn’t have to be. Here are some practical tips to make the process easier:

Align KPIs with business goals

Ask yourself: “What are we really trying to achieve?” Every supply chain KPI you choose should tie back to your core strategic objectives, whether that’s reducing operational costs, speeding up deliveries, or improving customer satisfaction.

🌻 Example: If your business aims to improve cash flow, focus on metrics like cash-to-sash cycle time and outstanding days sales. If customer experience is the priority, emphasize perfect order rate and order cycle time.

Keep KPIs measurable and actionable

Vague goals like ‘better performance’ won’t get you far. Focus on specific, measurable metrics that your team can influence.

🌻 Example: Instead of aiming to ‘improve inventory management,’ set a clear goal like ‘reduce inventory days of supply from 45 to 30 within the next quarter.’ Swap ‘Faster deliveries’ to shorten order cycle time by 10% over six months.

This makes progress easy to track and gives your team a clear target to work toward.

Choose what’s relevant

Not every metric matters to everyone. Tailor your KPIs to your audience.

🌻 Example:

- Warehouse teams: Track Inventory Turnover and Fill Rate to measure stock efficiency

- Procurement teams: Focus on Supplier Lead Time and Cost Per Order to streamline vendor performance

- Customer service teams: Prioritize Order Accuracy and Customer Order Cycle Time to keep customers happy

💡Pro Tip: Involve each team in selecting their KPIs. When teams have a say in what they track, metrics become their goals, not just company mandates.

Need more guidance on setting KPIs? Watch this video.👇

Less is more

Don’t overwhelm yourself or your team by tracking too many KPIs. It’s tempting to monitor everything, but that often creates confusion and dilutes focus. Instead, pick a few key supply chain metrics that truly matter.

- Start with 3-5 key KPIs for each area of your supply chain

- For inventory, instead of tracking 15 metrics, stick to Inventory Turnover, Days of Supply, and Fill Rate

Review KPIs regularly

KPIs aren’t set in stone; they need to evolve as your business and market conditions change. Regular reviews help keep them aligned with your current goals.

Conduct quarterly check-in. Assess whether your current KPIs are driving results. Are they still aligned with your goals?

🌻 Example: During a product launch, you might focus on on-time delivery and order accuracy but later shift to customer satisfaction and cost efficiency.

Implementing and Monitoring Supply Chain KPIs

Keeping track of supply chain KPIs can feel overwhelming. With so many monitoring processes, losing sight of the bigger picture is easy. For this, you need software that helps implement and monitor supply chain KPIs.

Tools and technologies to monitor KPIs

The right tools make it easier to gather, organize, and analyze data in real time. Here are some essential tools to consider:

- Business intelligence (BI) software: Provides real-time dashboards and visualizations to track performance and spot trends quickly

- Data analytics platforms: Helps analyze historical and real-time data to uncover insights and identify areas for improvement

- Enterprise resource planning (ERP) systems: Integrates data across departments, ensuring accurate and consistent KPI tracking

- Supply chain management software: Monitors logistics, inventory, and supplier performance, offering detailed visibility into supply chain KPIs

A great tool doesn’t just show you the numbers; it connects the dots between your supply chain metrics and business goals, helping you make smarter, faster decisions.

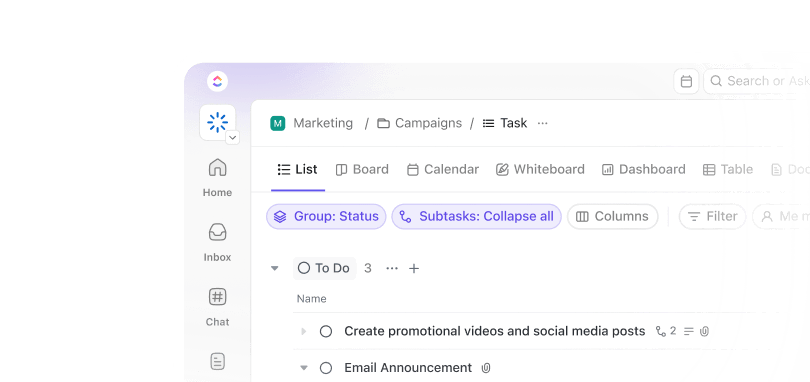

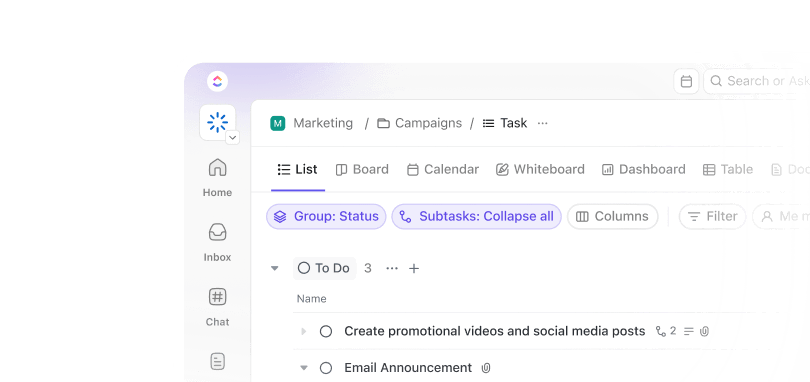

does exactly that. It is a comprehensive platform that simplifies KPI tracking, analysis, and action to monitor your supply chain metrics in one place with a supply chain KPI dashboard. Here’s how can help you stay on top of your KPIs:

Goals to simplify KPI tracking

Goals makes it easy to set, track, and measure progress toward your key KPIs. You can define and break specific targets into actionable steps tied to real-time progress tracking.

For example, inventory mismanagement drives up total supply chain costs and ties up working capital. Here’s how Goals can tackle the problem:

Set a goal to reduce excess inventory by 25% within the next quarter. Break this down into actionable steps, such as:

- Implementing clearance strategies for slow-moving stock through discounts or bundles

- Refining demand forecasts to align inventory levels with actual sales trends

- Negotiating with suppliers for more flexible minimum order quantities

As tasks get completed, updates progress automatically, so you always know how close you are to hitting your goal.

Dashboards for real-time insights

Dashboards give you a real-time, customizable view of your supply chain KPIs to make faster and more informed decisions.

For example, delivery delays can hurt customer satisfaction and damage your reputation. With , you can set up a real-time supply chain metrics dashboard to track on-time delivery rates using charts and progress bars. The data updates automatically, making it easy to spot bottlenecks such as delays caused by insufficient warehouse staffing.

Whether inventory, delivery times, or costs, ’s KPI Dashboards keep everything clear and centralized. It helps you identify problems early, streamline business operations, making performance tracking simple and actionable.

📮 Insight: 92% of knowledge workers risk losing important decisions scattered across chat, email, and spreadsheets.

Without a unified system for capturing and tracking decisions, critical business insights get lost in the digital noise. With ’s Task Management capabilities, you never have to worry about this. Create tasks from chat, task comments, docs, and emails with a single click!

Integration with ERP systems

Managing on-time delivery can be challenging, especially when dealing with multiple suppliers and tight deadlines. Delays in manual updates or miscommunication between teams often result in late shipments, unhappy customers, and rising costs.

Integrations works seamlessly with Enterprise Resource Planning (ERP) systems, pulling real-time data directly from your supply chain operations. Shipment status updates automatically populate into custom fields like expected delivery date, current status, and carrier details. Your team gets instant visibility into late or delayed shipments.

You can also use Automations to trigger notifications when a shipment is delayed or risks missing its actual delivery date. For example, if a shipment’s ETA slips by more than 24 hours, the logistics team gets alerted to act immediately. Procurement, logistics, and customer service can collaborate in real time to update customers or adjust timelines.

The outcome?

Late shipments drop as automated alerts and real-time data keep your team proactive, boosting delivery reliability and customer trust.

Manage KPIs with templates

Managing KPIs in the supply chain often feels like juggling order accuracy, delivery timelines, inventory turnover, and supplier efficiency, all while ensuring alignment across teams. Without the right tools, this can lead to silos, delayed updates, and missed opportunities. The KPI Template makes it simple to monitor progress and stay organized.

Imagine reducing your Inventory Days of Supply (IDS) from 45 to 30 while improving order accuracy and on-time delivery. With Custom Fields like target value, actual value, and progress, you can assign specific supply chain metrics to each team, monitor them in real time, and take immediate corrective action when performance dips.

Real-Time Alerts for KPI Deviations

Waiting until the end of the month to identify performance issues can be costly. enables real-time alerts to notify teams immediately of KPI deviations so they can act proactively.

Example use cases:

- ⚠️ Low fill rate alert: If the fill rate drops below 90%, triggers an alert to the inventory team

- ⏳ Delayed order notification: If an order exceeds the expected cycle time, the logistics team is notified

- 🔄 High C2C cycle time warning: If cash-to-cash cycle time increases beyond a threshold, finance teams receive an alert

How to Set Up KPI Alerts in ?

- Use Dashboards to visualize real-time KPI performance

- Set Automations to trigger notifications based on KPI thresholds

- Use Goals to monitor progress and update stakeholders automatically

- Integrate with ERP Systems to sync supply chain data and automate alerts

integrates seamlessly with email, Slack, and Microsoft Teams, ensuring alerts reach the right people instantly so KPI deviations are addressed before they escalate.

Take Charge of Your Supply Chain With

Managing supply chain KPIs doesn’t have to be complicated. With ’s powerful tools like Goals and Dashboards, you can easily track, analyze, and act on key metrics in real time for effective supply chain management. From setting clear objectives to automating reports and integrating with ERP systems, simplifies every step of the process.

It combines real-time tracking, automated reporting, and seamless integrations to provide the clarity and control needed to improve efficiency, reduce supply chain costs, and deliver results.

Whether optimizing your inventory-to-sales ratio, shortening cycle times, or improving order accuracy, turns data into action in one easy-to-use platform.

Take control of your entire supply chain performance today. Sign up for and see measurable results faster.

Everything you need to stay organized and get work done.