The automobile industry is going through a moment of evolution that we are all very aware of, especially given the energy transition that we are witnessing. China appears to be a leading country in this technological revolution and its manufacturers are demonstrating this with a multitude of models that lay the foundation for the present and future of the automobile.

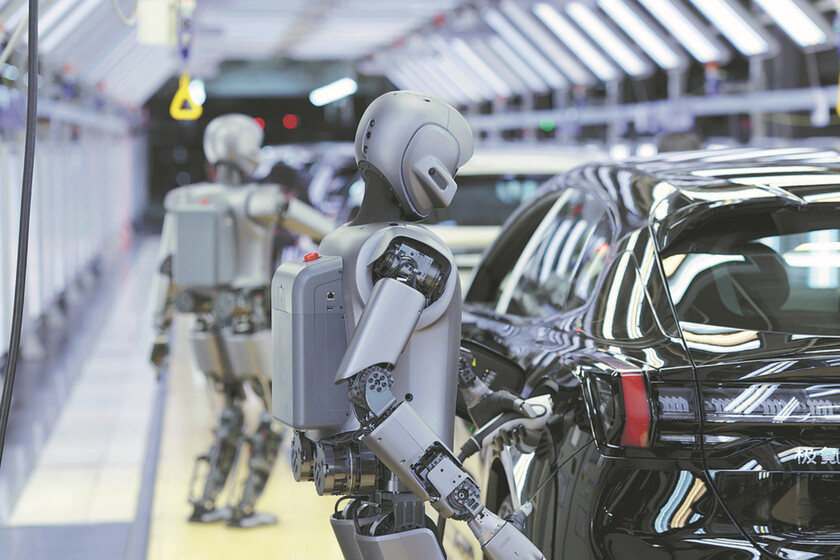

There is not only a technological revolution in many of the vehicles that we see on the streets, but also in their manufacturing process. And before the end of the decade, at least one manufacturer will achieve a fully automated assembly line. This is the conclusion reached by analysts at Gartner and Warburg Research. China is leading the race to open the first “dark factory”, factories where robots work without the need for lighting or human presence, which could forever change how cars are made. Below these lines we tell you all the details.

Why it is important. It is not just about robots replacing people in specific tasks, but about the total elimination of workers on assembly lines. China already has a wide range of “dark factories”, factories with assembly lines where there is hardly any lighting and are operated by autonomous robots. However, car assembly has not yet been 100% automated, since the process still requires human hands.

This would mark a turning point where artificial intelligence, humanoid robotics and digital manufacturing converge to redefine automotive production.

Pedro Pacheco, research vice president at Gartner, tells Automotive News Europe that a U.S. or Chinese manufacturer will “probably be the first to create a line with 100% automation by the end of this decade,” and that several players in those markets “are already implementing disruptive manufacturing processes and showing more focus on humanoid robots.”

Robotics and redesign. Until now, wiring installation and cabin components have been the only elements of the assembly line that are not typically fully automated, Pacheco explains. From the media they say that manufacturers that make the leap towards total automation will do so through two routes: adding advanced robotics and redesigning vehicles to facilitate automated assembly.

Automotive News Europe mentions splitting the wire harness into sections or integrating it directly into the body panels as an example. Another strategy is to not completely assemble the “body in white” before assembling the passenger compartment, thus facilitating access to the passenger compartment.

The protagonists of change. Hyundai Motor Group plans to deploy humanoid robots from Boston Dynamics at its Georgia manufacturing complex starting in 2028, it announced at CES in Las Vegas. The South Korean company aims to produce 30,000 robots per year and achieve production-scale deployment.

Mercedes-Benz, for its part, has launched a pilot project with humanoid robots that could begin working alongside assembly line employees before 2030. And Tesla is already manufacturing its Optimus robots on a limited scale in California, with Elon Musk’s vision of creating an army of robots that help in its factories and take on other tasks that involve repetition of processes.

Figures. According to Accenture, the integration of generative, agentic and physical artificial intelligence with robotics and digital twin technology is already helping to significantly improve factory efficiency, with “enormous potential” to reduce costs and time to market by up to 50% or even more.

McKinsey adds that $150 billion annually in potential economic value could be unlocked by accelerating R&D at large auto companies. In addition, 12 of the top 25 manufacturers are already running pilots with advanced robotics in their facilities, as shared by the analysis firm Gartner.

The debate on employment. Total automation does not necessarily have to translate into massive job losses, although it is certainly an issue that causes concern among unions. Workers could be reassigned to support functions such as maintenance, engineering, logistics, inspection or materials management, according to Pacheco. With proper training, employees could also engage in AI supervision, robotics maintenance, and software development.

The International Labor Organization anticipates that, although some routine and manual tasks will be reduced, many jobs will change their content and new jobs will emerge.

And now what. China is the favorite to inaugurate the first completely robotic factory, but everything indicates that the United States is not going to be left behind either. Warburg Research analyst Fabio Hölscher believes that it is “not unrealistic” to expect to see the first automotive “dark factory” in China by 2030.

Cover image | ChinaDaily

In WorldOfSoftware | That cars in Germany travel at 300 km/h is due to one reason only: their roads are prepared for it.