The software-defined era is not coming – it’s here

Industrial organizations face a fork: continue with hardware-first upgrades that lock systems into decades-long cycles, or pivot to a software-first approach that unlocks flexibility, speed and sovereignty in operational technology. Manufacturers, energy firms and plant engineers are increasingly choosing the latter as regulatory and operational pressures mount. The result is the rise of a true software-defined era that prioritizes interoperability, rapid iteration and control over equipment and data flow.

Why software-first beats a hardware-bound setup

Traditional modernization instincts push procurement teams toward new machines and bundled hardware-software systems. That feels safe: hardware is tangible and familiar. But hardware cycles span decades while market, compliance and sustainability pressures change annually. A hardware-first strategy therefore trades short-term capacity gains for long-term rigidity and vendor lock-in – the exact opposite of resilience. By contrast, software-first modernization evolves in shorter cycles, enables continuous improvement, and can unlock capacity and value that hardware alone cannot deliver.

The software-defined era reframes industrial architecture around a flexible, open software layer that connects and orchestrates assets. Three practical outcomes:

- Independence and agility: Organizations can experiment and iterate quickly without being trapped by single-vendor stacks.

- OT sovereignty: Engineers regain control of their operational environments by choosing best fitting components and open integrations.

- Sustainability and resilience: Software allows smarter resource management and gradual upgrades, lowering cost while improving compliance with new rules such as CRA and NIS2.

COPA-DATA’s zenon software platform enables this transition: keeping organizations independent and agile, embracing openness and freedom of choice, and helping customers regain control of their plants through a software-first mentality.

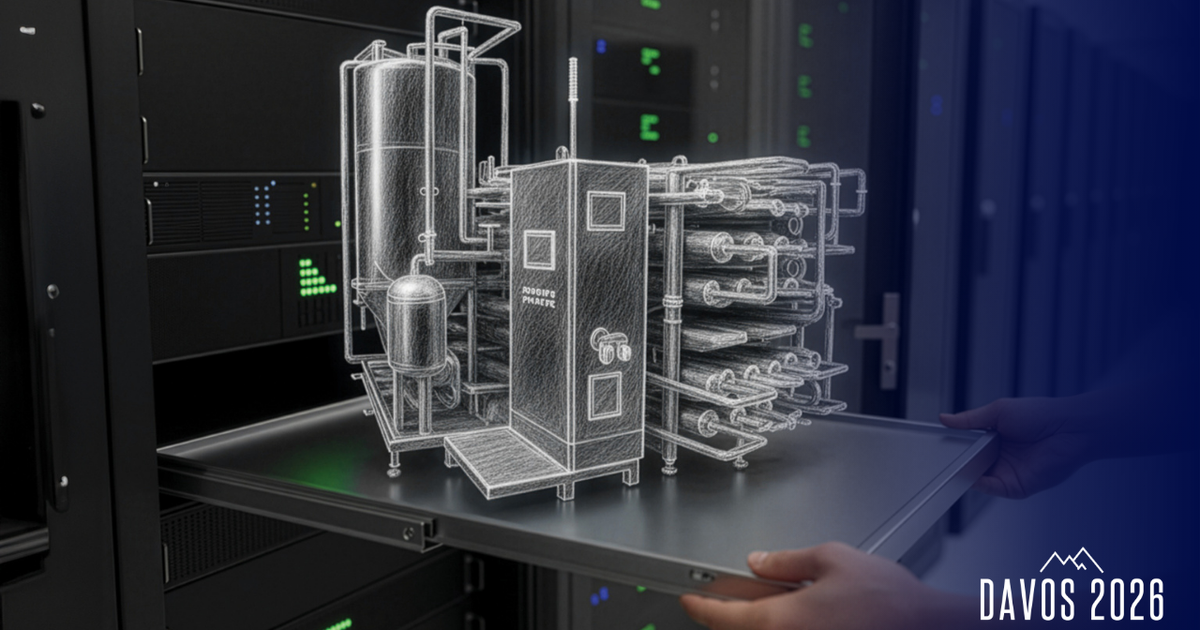

Plug & Produce: The Rise of Modular Production

Modular production or “Plug & Produce” transforms plants into reconfigurable, software-led ecosystems where functional modules are swapped and orchestrated like software components rather than rebuilt as new hardware. Orchestrated by a central process orchestration layer such as zenon, this approach accelerates scale-up from lab to full production, slashes changeover time, reduces waste, and breaks vendor lock‑in while protecting existing assets and enabling continuous improvement.

zenon OpenDCS for faster, compliant production

Built as a software-defined, hardware independent control layer, zenon OpenDCS delivers modular, scalable process automation tailored for pharmaceutical, life sciences and other process industries. By decoupling the DCS software from vendor-specific hardware, including virtualized platforms, it enables rapid orchestration of field equipment, leverages Automated Engineering to shorten engineering cycles, and removes traditional vendor lock-in to accelerate time to market while keeping production compliant.

The software-defined era awakens organizations to new models of innovation: shorter development cycles, less vendor lock-in, and stronger OT sovereignty. For manufacturers and energy operators ready to embrace change, software is the key to smarter, cleaner, and more resilient operations with less wholesale replacements necessary. Modernize through software first, reclaim control, and build systems fit for the next decade and beyond.

This advertiser content was paid for and created by Acumen. Neither CBS News nor CBS News Brand Studio, the brand marketing arm of CBS News, were involved in the creation of this content.