Managing a supply chain today is no easy job. You’re constantly trying to meet the evolving customer expectations. Adding to it is the immense pressure of cutting down costs, streamlining workflows, and improving efficiency, and dealing with geopolitical disruptions.

To do this, you need complete visibility into your supply chain. This means that all supply chain processes need to be 100% transparent. And that’s where a supply chain dashboard comes in.

A well-built supply chain dashboard turns complex, scattered data into clear, actionable insights. Instead of spending hours digging through spreadsheets to check inventory levels or reconcile supplier performance reports, you can use the dashboard to spot issues in real time and act quickly to avoid disruptions.

In this blog post, we’ll walk you through what a supply chain dashboard should include, the supply chain KPIs that matter, and how to build a dashboard that works for your team.

Supply Chain Dashboard: What to Track & How to Build One

What Is a Supply Chain Dashboard?

A supply chain dashboard is a centralized, visual tool that displays real-time data and key performance indicators throughout the entire supply chain, from procurement and inventory to production, logistics, and delivery. It brings together scattered data from across existing systems, such as your enterprise resource planning system, warehouse management system, transportation management system, and supplier portals, and turns it into real-time insights.

The dashboard helps you catch issues early, monitor KPIs that matter, and make smarter, faster decisions — whether you’re managing delays, balancing stock, or responding to a last-minute demand spike.

Why Use a Supply Chain Dashboard?

As an operations manager or a logistics professional, you need proactive data for strategic planning. This means you need live updates across the supply chain, from inventory levels and freight costs to supplier performance and on-time delivery rates.

Here’s why you need to have a supply chain dashboard:

- Data-driven decisions: Pulls data from inventory tools, WMS, TMS, ERP, order management, and supplier platforms and turns it into decision-ready insights. With this data, you can identify trends

- Efficiency and time savings: Automates the reporting process, so that you don’t have to pull data from siloed systems manually

- Improved collaboration: Centralizes data and aligns teams across procurement, logistics, and operations on shared goals and priorities

- Performance tracking: Tracks critical supply chain key metrics, such as order accuracy, fulfillment rate, and inventory planning and turnover, to help optimize performance and enhance efficiency

- Risk reduction: Provides situational awareness around weather events, labor shortages, and demand shifts so your processes stay agile and adapt quickly

Key Metrics to Track in a Supply Chain Dashboard

When designing a supply chain dashboard, here are the most important metrics to include:

| Metric | What it means | Why it matters |

| Inventory Turnover Rate | Shows how often inventory is sold and replaced over a given period | Helps optimize stock levels, avoid excess inventory, and reduce holding costs |

| Order Fulfillment Rate | The percentage of orders successfully delivered on time and in full, compared to the total number of orders | Directly impacts customer satisfaction and operational efficiency |

| On-Time Delivery (OTD) | The percentage of orders delivered by the promised date | Ensures customer expectations are met and delays are minimized |

| Lead Time | The total time it takes from placing an order with a supplier to receiving goods or services | Shorter lead times help reduce stockouts and improve inventory planning |

| Supplier Performance | Tracks how well suppliers are meeting quality, cost, and delivery expectations | Identifying strong and weak suppliers enables better sourcing decisions and helps manage risks |

| Transportation Costs | The sum total of shipping and fuel costs, labor, and packaging expenses | Helps optimize logistics, reduce waste, and identify opportunities for cost-saving strategies |

📮 Insight: 21% of respondents want to leverage AI to excel professionally by applying it to meetings, emails, and projects.

While most email apps and project management platforms have AI integrated as a feature, it may not be seamless enough to unify workflows across tools.

But we cracked the code at ! With ’s AI-powered meeting management features, you can easily create agenda items, capture notes from meetings, create and assign tasks from meeting notes, transcribe recordings, and more—with our AI notetaker and Brain. Save up to 8 meeting hours per week, just like our clients at Stanley Security!

Types of Supply Chain Dashboards

Let’s take a look at some supply chain dashboard examples.

1. Operational supply chain dashboard

This supply chain dashboard helps you track daily goods movement and ensures your operations meet service-level agreements, improving supply chain performance.

👤 Used by: Supply chain managers, plant managers, distribution center supervisors

🛠️ Tools commonly used: Dashboards, Zoho Analytics

✅ Primary KPIs tracked:

- Order cycle time: The total time it takes from when a customer places an order to when they receive it, including order processing, picking, packing, shipping, and delivery

- Inventory turnover rate: The number of times inventory is sold and replaced during a given period

- Fill rate: The percentage of customer demand that is met through immediate inventory availability without backorders or delays

2. Inventory management dashboard

A comprehensive inventory management dashboard for managing inventory flow across multiple storage locations or channels.

👤 Used by: Inventory planners, warehouse managers

🛠️ Tools commonly used: NetSuite, Cin7

✅ Primary KPIs tracked:

- Stockout frequency: The number of times an item is out of stock during a specific period

- Dead stock value: The total value of inventory items that haven’t been sold or used for a significant period

- Inventory turnover ratio: The number of times inventory is sold and replaced within a specific time period

3. Logistics dashboard

This dashboard focuses on shipment tracking, last-mile delivery, and controlling freight costs. It ensures that goods are moving efficiently from point A to B and allows logistics teams to reroute or proactively escalate delays.

👤 Used by: Logistics coordinators, transportation managers

🛠️ Tools commonly used: ShipBob, FreightPOP

✅ Primary KPIs tracked:

- Freight cost per unit: Total freight cost divided by the number of units shipped

- Carrier performance: A measure of how well third-party carriers meet service expectations, including timeliness and condition of goods

- In-transit inventory: Value or quantity of goods that have been shipped but not yet received at the destination

4. Supplier Performance Dashboard

You can use this type of supply chain dashboard to monitor and evaluate supplier reliability and quality over time. Your logistics teams can assess procurement challenges, negotiate better terms, and maintain compliance across sourcing operations using this dashboard.

👤 Used by: Procurement managers, vendor relations teams

🛠️ Tools commonly used: Coupa, Jaggaer

✅ Primary KPIs tracked:

- Supplier defect rate: Percentage of materials or products received from suppliers that do not meet quality standards

- Lead time consistency: Measures how consistently a supplier meets the expected or agreed delivery lead times

- Contract compliance score: Tracks how closely a supplier adheres to the agreed contractual terms, such as price, delivery, quality, service levels, etc.

5. Demand forecasting dashboard

A demand forecasting dashboard predicts customer demand accurately so you can plan inventory, production, and procurement. Instead of relying on last year’s sales numbers, this dashboard pulls in real-time and historical data (sales, seasonality, promotions, market trends, etc.) to surface patterns, spot shifts, and model future demand.

👤 Used by: Demand planners, sales, and operations planning teams

🛠️ Tools commonly used: Excel + BI integration, SAS Forecasting

✅ Primary KPIs tracked:

- Demand vs. actual sales: Compares forecasted customer demand and the actual sales recorded

- Seasonal trend patterns: Recurring sales patterns that occur at specific times of the year, like holidays, back-to-school, and summer spikes

- Historical sales volatility: Degree of fluctuation in sales data over time

6. Risk management dashboard

A risk management dashboard gives you real-time visibility into vulnerabilities across your supply chain—from supplier risks and transportation delays to geopolitical threats, supplier bankruptcies, and compliance gaps.

👤 Used by: Risk analysts, business continuity managers

🛠️ Tools commonly used: Resilinc, Fusion Risk Management

✅ Primary KPIs tracked:

- Supply chain disruption events: Number of events that interrupt the normal flow of goods and services in the supply chain (e.g., natural disasters, strikes, cyberattacks, supplier shutdowns)

- Contingency stock levels: The amount of additional inventory explicitly held for use during emergencies or supply chain disruptions

- Impact probability matrix: Potential supply chain risks plotted on a heatmap by their likelihood (probability) and consequences (impact)

7. Financial supply chain dashboard

The financial supply chain dashboard bridges the gap between the physical movement of goods and the flow of money tied to it. Ops and finance teams use it to gain shared visibility into how supply chain activities impact working capital, cash flow, and overall financial health in real time.

👤 Used by: CFOs, cost analysts

🛠️ Tools commonly used: , Tableau

✅ Primary KPIs tracked:

- Cost per unit: Total cost incurred to produce or procure one unit of product, including materials, labor, overhead, and logistics

- Cost-to-serve: Total cost of servicing a specific customer or product line, factoring in warehousing, transportation, customer service, returns, and administrative efforts

- Working capital tied up in inventory: The amount invested in inventory that is not immediately generating revenue

8. Order tracking dashboard

An order tracking dashboard pulls back the curtain on your entire order lifecycle—from purchase creation to shipment, delivery, and final fulfillment.

In supply chain management, you want a unified view of every step of the order journey. And this supply chain management dashboard helps you do just that.

👤 Used by: Fulfillment managers

🛠️ Tools commonly used: , Salesforce Service Cloud

✅ Primary KPIs tracked:

- Orders by status: A real-time breakdown of where each order stands in the fulfillment process

- Average fulfillment time: The time it takes from when an order is placed to when it’s shipped out

- Order accuracy rate: Percentage of orders that were delivered exactly as requested (correct items, quantities, and packaging)

How to Build a Supply Chain Dashboard

Step 1: Define your goals and audience

Define upfront whether the dashboard is for strategic oversight, operational control, or exception management, and design it accordingly.

For example, supply chain heads or finance teams need high-level summaries for strategic planning while warehouse managers and logistics coordinators need operational dashboards for day-to-day actions.

🎯 Common goals might include:

- Monitoring KPIs: Inventory turnover, order fulfillment rate

- Identifying bottlenecks: Delayed shipments, inventory shortages

- Improving decision-making: Demand forecasting, supplier performance

Then, tailor the level of detail and visualization to the audience’s needs.

💼 Supply chain stakeholders can include:

- Procurement team: Track supplier performance and lead times

- Warehouse supervisors: Focus on throughput, productivity, stock locations

- Logistics coordinators: Want insights on transport efficiency, delivery delays

Use Goals to align your dashboard metrics with strategic objectives and track progress in real-time. With Targets, you can tie specific milestones and KPIs to each goal and see how every data point on your dashboard relates to a larger business outcome.

Use number targets when you’re tracking progress toward a numerical objective, such as ‘Reduce average order processing time to under 24 hours’. Currency Targets are perfect for cost-related goals in your supply chain. When you want to track binary milestones, such ‘Real-time shipping updates feature enabled – Yes/No’, switch to True/False Targets.

💡 Pro Tip: Use Goal Folders in to organize your goals by different areas of the supply chain dashboard, such as Inventory, Logistics, and Procurement.

Step 2: Identify relevant data sources

A supply chain dashboard is only as strong as the data it pulls from.

Start by identifying all key systems and tools that house supply chain data across your organization.

🖥️ Common data sources to consider:

- ERP systems: Core data on manufacturing, finance, procurement processes, and inventory levels

- Inventory management software: Stock levels, SKUs, reorder points, and warehouse movements

- Order management tools: Data on customer orders, fulfillment status, delivery times, and returns

- WMS: Data on inbound shipments, picking accuracy, storage utilization, and dispatch timelines.

- TMS: Carrier performance, shipping costs, delivery tracking, route optimization insights.

- Supplier portals or SRM systems (Supplier Relationship Management): Lead times, supplier scorecards, contract terms, compliance data.

- Demand planning or forecasting tools: Sales forecasts, historical demand patterns, promotional uplift factors.

- Customer Service Platforms (CRM Systems): Returns, complaints, and feedback loops that highlight fulfillment or delivery issues.

At this stage, you must document data ownership for each source. Know who maintains it, how often it’s updated, and any known gaps — this will save massive headaches during dashboard integration and validation.

Step 3: Select the right KPIs

Every KPI you decide to add to the supply chain dashboard should answer a business-critical question. Or it could signal an operational risk that needs attention. Your end goal can range from improving fulfillment speed, reducing carrying costs, shortening delivery timelines, or de-risking your supply chain.

📈 To choose the right KPIs, start by asking:

- What decisions do we need to make with this dashboard?

- Which metrics reflect progress toward our goals?

- What data is available, accurate, and updated frequently?

The KPI Template is a flexible and customizable framework designed to track performance across procurement, inventory, logistics, and delivery in one centralized space.

The template features a Progress Board view that displays OKRs based on their progress status. With a high-level overview for quickly identifying which OKRs are at risk, your team can develop and implement effective mitigation strategies.

There’s also the Timeline view, which displays each OKR along a timeline based on its start and due dates and highlights which departments are working on specific OKRs during any given time period.

🤝🏻 Friendly Reminder: Avoid the temptation to track everything. A well-designed dashboard should focus on the few metrics that matter most, tailored to the needs of the dashboard’s audience (executives, managers, or operations teams).

Step 4: Choose a dashboard tool

The next step is to bring your supply chain analytics to life on a dashboard. Remember that not every dashboard tool will suit your supply chain’s complexity or data environment.

When you’re choosing a dashboard tool, consider the following aspects:

- Data integration: Can it pull data easily from your ERP, WMS, or TMS without manual uploads?

- Real-time updates: Does it refresh frequently enough to support operational decision-making?

- User customization: Can different stakeholders (procurement, logistics, finance) create views tailored to their needs?

- Scalability: Will it still work as you add new suppliers, SKUs, or warehouses?

📊 Here’s how you can use different widgets to make your KPI dashboard both insightful and visually engaging:

- Bar/line chart: Track inventory turnover, order cycle time, or supplier lead times over weeks or months

- Progress bar: Track goals such as improving delivery accuracy or meeting production targets

- Pie charts: Show how inventory is distributed across different product categories or warehouses

Dashboards in offer a variety of widgets to track different aspects of your supply chain KPIs and metrics. You can use filters to view data for specific periods and create custom views tailored to various roles within your team, such as warehouse managers or procurement officers.

Step 5: Design the layout for clarity

When a user opens the dashboard, their eyes should land on the most important insights first, without scrolling or searching.

How do you do this? Start by prioritizing the information hierarchy. This means placing the most critical metrics at the top of the dashboard so they’re immediately visible. Supporting or secondary metrics can be grouped lower down or behind drill-down views.

You also know that your supply chain teams aren’t always sitting at a desk. Your warehouse managers, logistics coordinators, and field teams may check dashboards on tablets or phones during operations.

The dashboard layout must be clean, legible, and easy to interact with across different screen sizes. With responsive design, anyone, regardless of their location, can quickly get relevant insights.

📌 Here’s how to make your dashboard easy to interpret at a glance:

- Avoid cluttering: Choose metrics that drive decisions and only include KPIs that are critical for the user’s role

- Group information logically: Organize widgets or sections into thematic blocks to help users find what they need faster

- Keep navigation intuitive: Use clear labels for each section or widget, and color-coded flags to highlight exceptions

Using for Supply Chain Dashboards

, the everything app for work, helps supply chain managers plan procurement schedules, track shipments, optimize inventory, collaborate with suppliers, and monitor KPIs in one centralized workspace.

Let’s take a closer look at its robust task management, visualization, automations, and collaboration features for your supply chain dashboard.

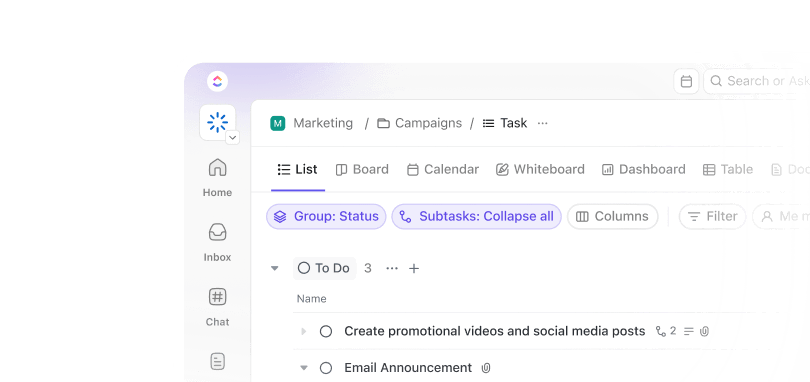

Custom dashboards with real-time widgets

Dashboards in are fully customizable. Add widgets, arrange them in a grid layout or something more open-ended, drag and drop to move them around, resize them, and group them to put related KPIs together.

In addition to bar/line charts, progress bars, and pie charts, you get a ‘Task List’ widget to track who’s doing what, what’s overdue, and what’s already wrapped up. The ‘Text/Note’ widget lets you drop in weekly updates, quick explanations, or notes on any weird data spikes.

As tasks are updated, statuses shift. Deadlines get closer. Goals move forward.

Your dashboard updates instantly without manual effort. There’s no need to refresh pages or re-run reports. You’re always looking at the most current snapshot of your data.

Inventory and logistics tracking via List or Table views

’s List View is like a digital checklist, ideal for tracking what items are low on stock, which orders are delayed, or what’s coming in next. Each task in your list represents a product or batch, and you can use Custom Fields to add information that’s specific to your workflow.

Once your fields are in place, the Table View in converts your list into a mini database for your team. Now you can sort by stock level, group by status, or set filters to show only low-stock items or incoming shipments.

You can save the filtered views for different departments, from warehouse operations and finance to the procurement team.

Automations for order management and supplier updates

Warehouse management systems can get complicated fast. You’re tracking inventory levels, setting reorder points, processing orders, and managing vendor communications.

With Automations, you can set triggers, if/then actions, and conditions to automate repetitive tasks.

For example, when a new order comes in, you can automatically generate a task that captures all the essentials: customer information, item quantities, shipping instructions etc.

Collaboration features for distributed teams

Your suppliers, transportation teams, and procurement leads are all working from different locations. This is where all teams can use collaboration features to ensure everything moves smoothly.

You can easily discuss details, assign responsibilities, resolve issues, and track updates within the context of your work.

Need to collaborate on shared documents? Docs let multiple people edit, comment, and work together in real time. You can even attach files like invoices or order confirmations directly to tasks and projects, keeping everything organized in one place.

Tag a teammate with an @mention to make sure they never miss an important update or request.

And when you need faster conversations, Chat lets you create team-specific rooms. They support cross-functional supply chain groups that need to stay connected without switching between different apps.

Manage Your Entire Supply Chain Workflow With

Trying to manage your supply chain without a clear dashboard means you’re constantly jumping between spreadsheets, waiting on updates, and piecing together information from emails, meetings, and disconnected tools.

With ’s customizable dashboards, you can pull all your key supply chain metrics into one live view. Automations help by triggering tasks or alerts when inventory dips below a set level or a shipment is late.

Want to build a dashboard that makes updates, reports, and decisions move faster? Sign up on for free and get real time visibility across your supply chain.

Everything you need to stay organized and get work done.