Xiaomi’s smart factory in Changping, Beijing, stands at the forefront of a global manufacturing shift. This 96,900 square-yard facility uses advanced robotics and AI to operate without any human workers on site. This dark factory can produce smartphones much faster than other facilities, operating day and night. Factories like this signal a new era of manufacturing, a transformation that’s sweeping across China’s industrial sector. Similar factories are being explored in various sectors, from electronics to car manufacturing, and each is pushing the limits of automation and what can be done without human labor.

While dark factories improve efficiency, precision, and cut costs, this shift to fully automated manufacturing raises questions about the future of work and economic balance. Millions of traditional manufacturing jobs could be lost if the workforce were replaced by machines. AI is already taking some jobs, so the need for reskilling programs is greater than ever. In that sense, Xiaomi’s dark factory is both a promise and a warning. It represents the power of innovation while exposing the human costs that can accompany total automation.

The technological marvel of Xiaomi’s dark factory

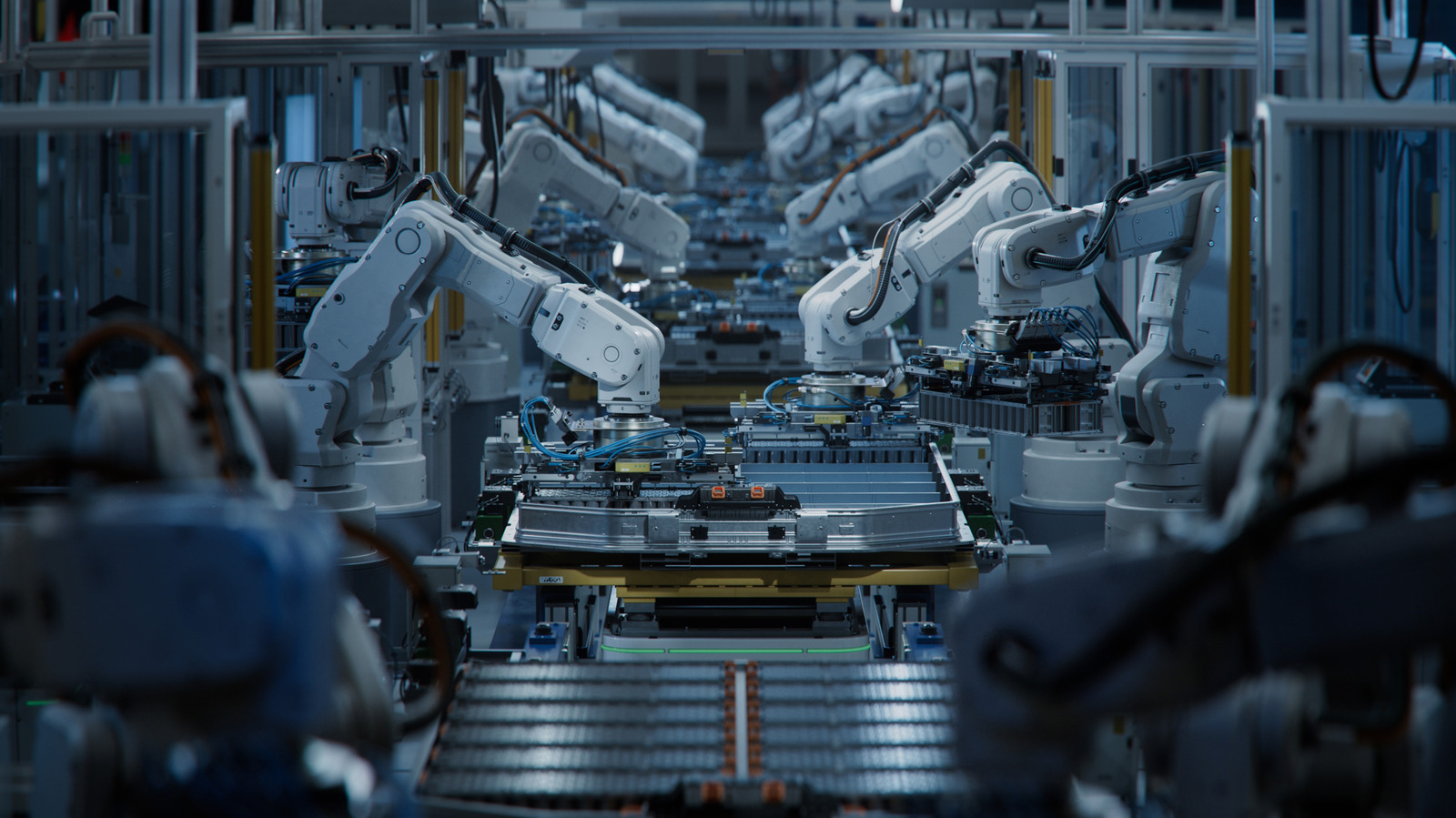

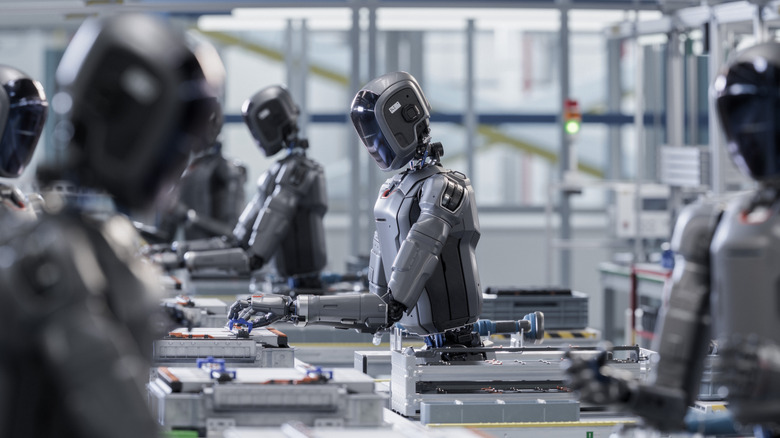

When we think of robot factories, the ones we’ve seen in sci-fi shows and movies quickly come to mind. It’s easy to imagine neon lights, shiny machines, perhaps even entire neighborhoods or cities controlled by robots. China’s robotics industry and Xiaomi’s dark factory aren’t too far off from that image and might be the most futuristic manufacturing plant in the world. Machines are doing all the work, and that enables continuous production without the limitations of human shifts, breaks, and supervision. The term “dark factory” stems from both the lack of humans and light. Without people, there’s no need to keep the lights on, as robots don’t need them to perform their tasks. Xiaomi also reduced the production costs by eliminating heating, lighting, and personnel costs, while increasing uptime and consistency.

Xiaomi’s factory incorporates advanced robotics, artificial intelligence, machine vision, and automated logistics. The manufacturing of smartphones is coordinated and handled by thousands of sensors and an AI-driven system. The assembly, inspection, material handling, and environmental control are all working without any human intervention. The facility’s automation platform, Xiaomi’s HyperIMP (Intelligent Manufacturing Platform), is the brain of the factory. It continuously monitors production, adjusts processes in real-time as needed, and controls quality standards.

With this level of automation, Xiaomi has a remarkable output. Company reports indicate that this dark factory can produce up to 10 million smartphones annually. That means, if working at full capacity, Xiaomi’s factory would produce an average of one smartphone per second.

The dark side of intelligent manufacturing

As robots are taking over human labor, not only at Xiaomi’s smartphone plant, China’s industrial landscape is being reshaped. This facility shows how automation can increase efficiency and reduce labor costs by replacing traditional assembly work with AI and robotics. But this shift, although profitable, involves big social and economic risks. As more factories adopt automation, millions of jobs might disappear. Hundreds of thousands of industrial robots are deployed annually for automation, which gives China a global lead in factory robotics but also reduces the demand for routine assembly and manual labor roles.

Workers who once relied on factory jobs face displacement. The demand for highly specialized roles such as robotics maintenance and AI system programming is increasing. Without robust retraining and reskilling programs, this will further increase the economic disparity within regions and between skilled and unskilled labor pools. Areas historically dependent on labor-intensive manufacturing may see shrinking job markets, the urban-rural divide could intensify, and education inequality might deepen.

With this in mind, the future of manufacturing will likely be a hybrid model, where autonomous systems would handle high-volume, repetitive tasks, while humans would focus on supervisory and maintenance work. It’s up to industry leaders and policymakers to invest in education and social support structures, which will ensure a smooth transition to automation.